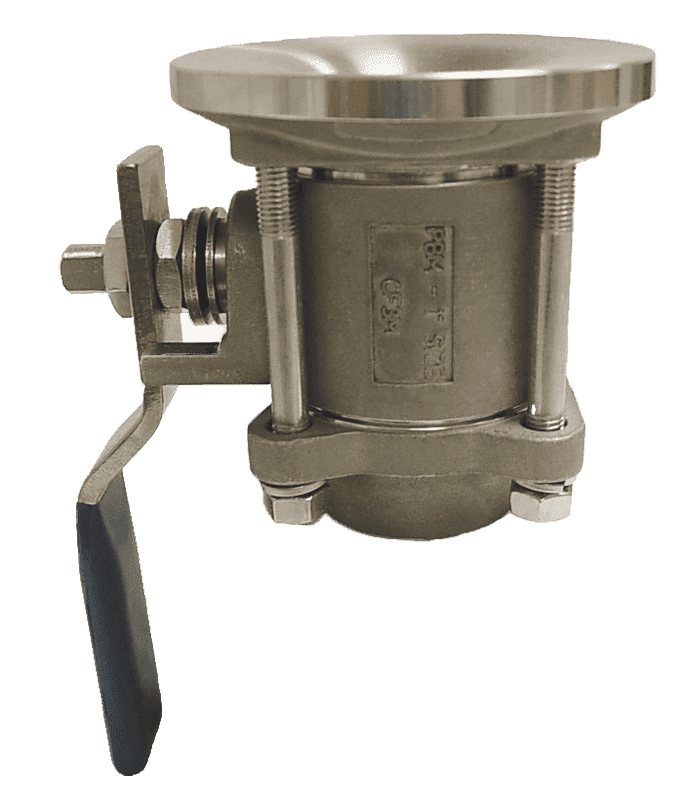

Firesafe Tank Bottom Valves

Tank Bottom Series 6, 1/2” – 3”

Two-Way Tank Bottom valves are suited for sanitary tank, vessel, and reactor applications. Angle Stem Flush Tank Bottom valves provide actuator clearance on jacketed or insulated vessels.

- Fire Rated, tested to API-607.

- FI Series Fire Rated Flush Tank valves have o-rings.

- Three-piece “swing-out” body design.

- Upstream and downstream bubble-tight sealing capability allows valve body cleaning and draining.

- True-Bore® design.

- Valves are rated to full vacuum.

- Material Test Report (MTRS) provided for wetted components.

- Surface finishes are achieved without the use of ADIs (Animal Derived Ingredients).

- Optional Fusible Link – A Spring Return Handle unit can be equipped with an optional fusible link specified to a customer’s required melt temperature, which closes the valve during fire conditions.

- Direct mount automation.

Product Specifications

Sizes

- 1/2” – 3”

Material

- 316/316L

- (ASTM A351 CF3M)

- Hastelloy® C276 and other materials

Temperatures

- Ambient for V-TEF™ to 400°F

- S-TEF® to 450°F

End connections

- Extended tube

- Hygienic clamp

- Compression ends (1/2” – 1”)

Seats & seals

- V-TEF™ or S-TEF® seats

- Graphite seals

- O-rings (EPR, FKM standard)

Stem packing material

- V-TEF™ or S-TEF®

- Graphite secondary seals

Body bolts & nuts

- 18-8 Stainless Steel, fully encapsulated

Maximum working pressure

- Up to 720 psig CWP depending on valve series, size and temperature

Temperatures

- Up to 450°F depending on seat and seal material

Polish

- Standard internal polish of 30 Ra ID

Find your perfect flow control solution