Key Technologies

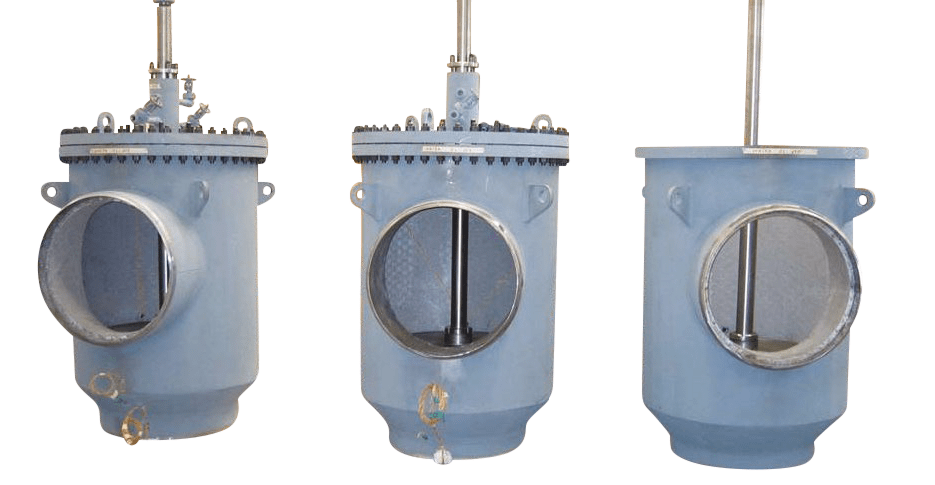

Isolation valves

IMI Remosa butterfly, check, gate, shut-off and slide valves are recognised for their high performance and reliability, as well as for being easy to maintain. We ensure that all components at risk of erosion can be replaced easily using the best available materials, such as high-end alloys, to protect them from the harshest environments.

Key Technologies

Hydraulic control systems and actuators

We’ve integrated our actuators and control systems with our valves to offer a top-notch control solution. Our hydraulic power and control unit actuators are customisable, reliable, and user-friendly. Our control systems can be safely installed remotely or directly on the HPCU, meeting hazardous area regulations.