Custom-engineered valves for petrochemical applications

We offer custom-engineered valves for critical applications in the petrochemical sector. Leveraging our decades of experience in the refining, chemical, fertiliser, ethylene, and ammonia industries, we have developed world-leading valve technologies designed to optimise plant performance and safety.

Our valve solutions excel in delayed coking, Catofin® (propane dehydrogenation), ethylene, and fluid catalytic cracking (FCC), meeting the specifications of process licensors such as UOP, Lummus, CB&I, and Exxon.

Drawing upon extensive expertise spanning decades, we have developed world-leading valve technologies meticulously designed to enhance plant performance and safety.

Chemicals

Chemical production relies on chemistry and engineering to create products like vitamins, oxygen, cosmetics, and raw materials. To maintain purity, clean production lines are essential. IMI valves endure high pressure, temperature, and corrosion in chemical production, while being made in contamination-free clean rooms, especially crucial for oxygen production.

Fertiliser & ammonia

Ammonia is crucial for fertilisers and various industries. IMI supplies valves for ammonia production, ensuring precise control under extreme conditions. Nitrogen-based fertilisers are vital for plants, and ammonia is produced by combining nitrogen from air with hydrogen. It is used to make nitrate fertilisers or mixed with carbon dioxide to create urea. Therefore, ammonia plants are commonly integrated into fertiliser production facilities.

Ethylene

Ethylene is a crucial building block for everyday goods. IMI is the leading supplier of severe service valves for ethylene production, including furnace isolation valves and a state-of-the-art double disc through conduit (DDTC) gate valve design. We also provide control, bypass, anti-surge, steam control, and isolation valves, with a substantial global presence in ethylene plants.

Global expertise and manufacturing

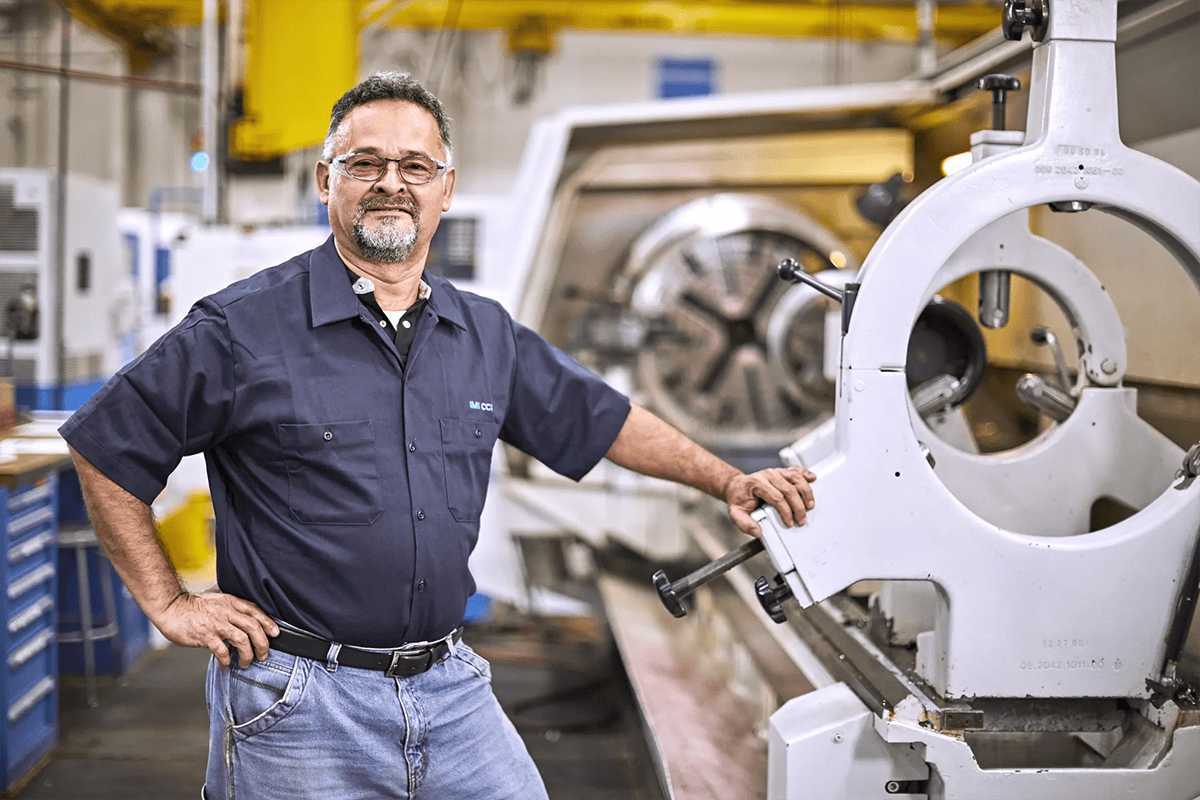

IMI’s dedicated team of over 2,900 experts, manufacturing facilities spanning 12 countries and a global network service, is committed to delivering precision-engineered flow control solutions, expert installation, and lifetime servicing. A deep understanding of the entire process enables us to provide tailored solutions that ensure unparalleled reliability and performance.

Petrochemicals articles

Company News

A day in the life of… Steve Freitas

Company News

Triple offset butterfly valve passes factory acceptance test for propa

Case Study

Triple offset butterfly valve boosts propane dehydrogenation plant pro