Reduce valve erosion

If left unchecked, flashing will reduce the operational performance and lifespan of the valve which is why IMI has created a new solution, EroSolve Flashing, to cope with flashing conditions. This solution can replace the whole valve or just the trim as needed. EroSolve Flashing solutions will reduce valve erosion and operational costs, resulting in better performance, less maintenance, and a longer valve lifespan.

Our custom designed EroSolve Flashing solutions can reduce the total cost of ownership by up to 40%, delivering improved flow control, and facilitating easier maintenance.

What is flashing?

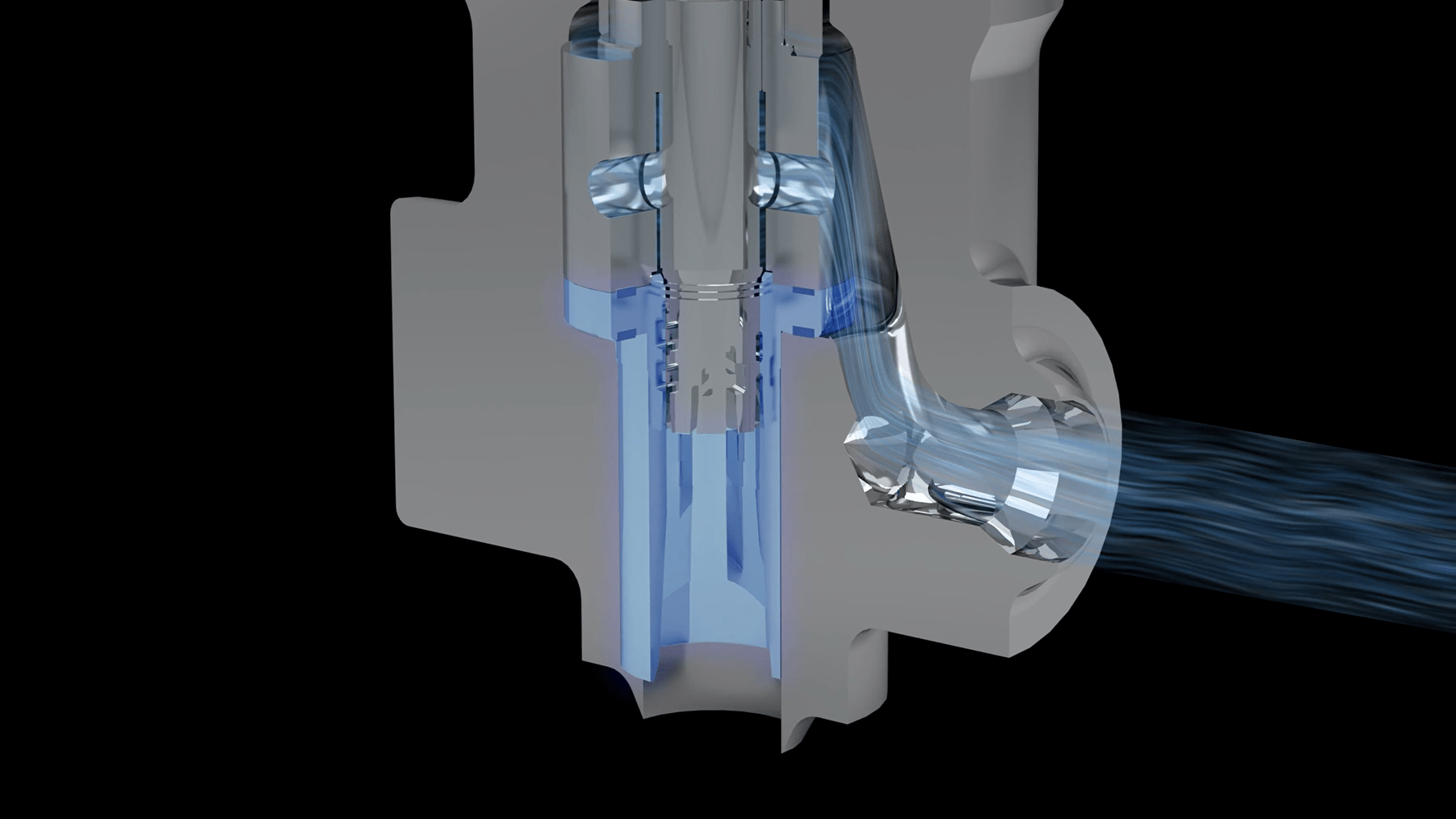

Flashing is a destructive phenomenon that occurs in many industries that use steam processes. Flashing occurs when the pressure of a fluid passing through a valve is lower than the same substance’s vapour pressure. This causes the fluid to boil – otherwise known as ‘flashing’. Flashing can both ‘choke’ the valve, reducing flow capacity through it, and can damage the valve itself through severe erosion.

Benefits of flashing solution

- Maximises valve performance in flashing conditions

- Lowers total cost of ownership by up to 40%

- Is available for both new and existing valve installations

- Delivers improved flow control

- Facilitates easier maintenance

- Increases valve lifespan

- Enhances operational safety

- Angle and globe options for different piping configurations

Angle and Globe options

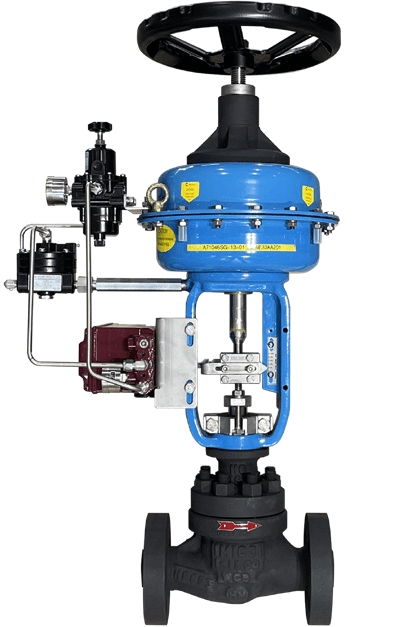

Angle Valve

860G-ESF/ 860H-ESF:

- Most effective option for controlling flashing

- Hardened trim material applied to trim to resist erosion

- Special seat design to maintain tightness, control leakage and improve performance

- Multi-path, multi-turn plug design moves flashing point, minimising damage to vital trim parts

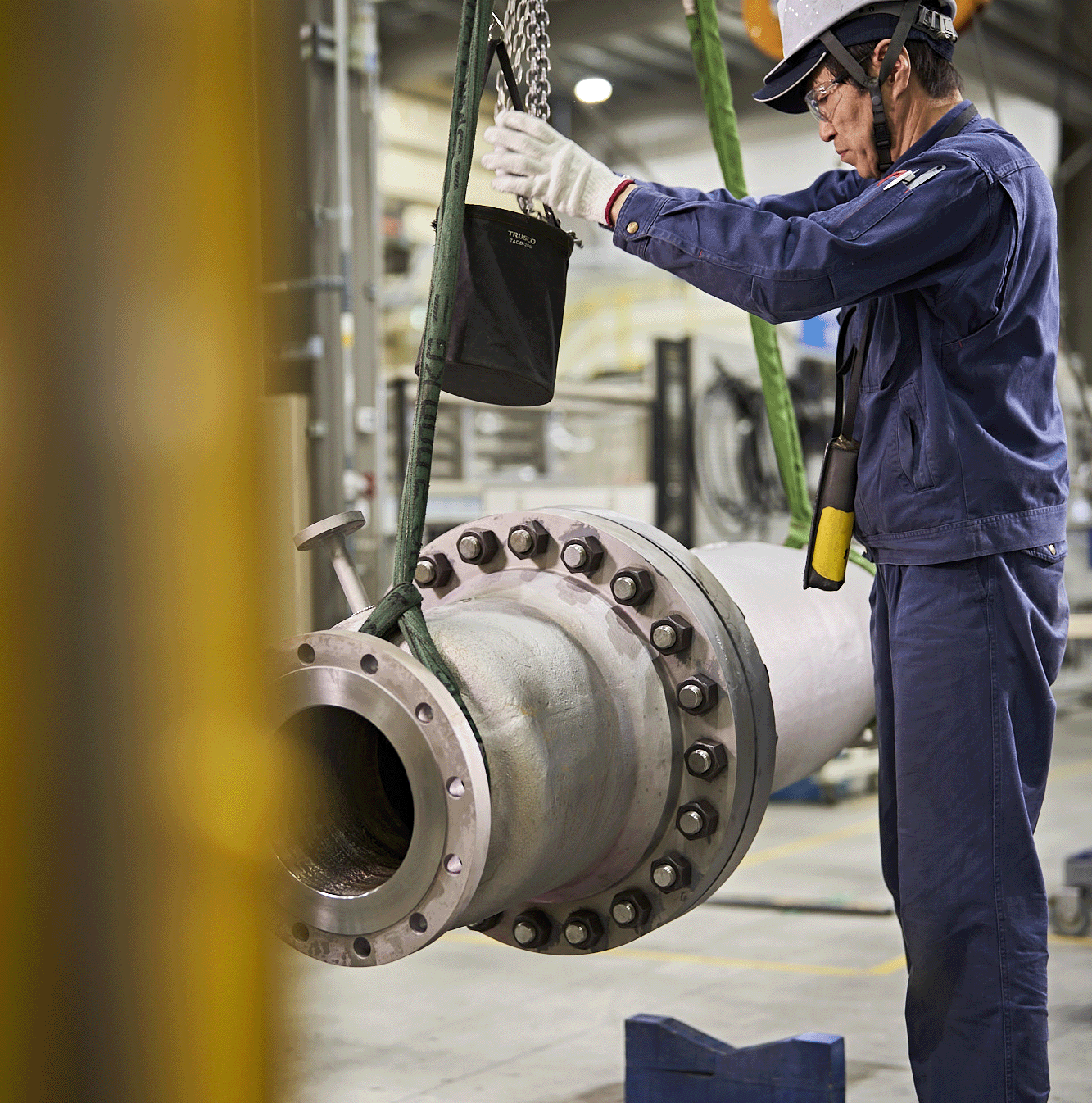

- Full valve or trim replacement options

- Applications up to 550°

- Valve sizes: 1”, 2”, 3”, 4”, 6”

Globe Valve

840G-ESF/ 840H-ESF

- Drastically improves performance and safety without modifying the pipe layout

- Seat basket placed inside valve, taking the damage instead of the valve body

- Customised seat basket creates back pressure, reducing the velocity of liquids downstream and reducing the pressure drop

- Easier and cheaper to fit, in-situ replacement

- Machined or additive manufactured seat baskets to match operating conditions