Maximise industrial efficiency

Industrial facilities face significant challenges with control valve issues, such as unwanted vibrations that lead to stem and plug coupling breakage. This compromises flow control, creates excessive noise, and reduces operational efficiency. IMI offers a solution: comprehensive valve trim upgrades. These upgrades solve these expensive and time-consuming problems without the need to replace valves or halt operations. With our trim upgrades, businesses can maintain uninterrupted productivity, minimise downtime, and enjoy the cost benefits of improved efficiency.

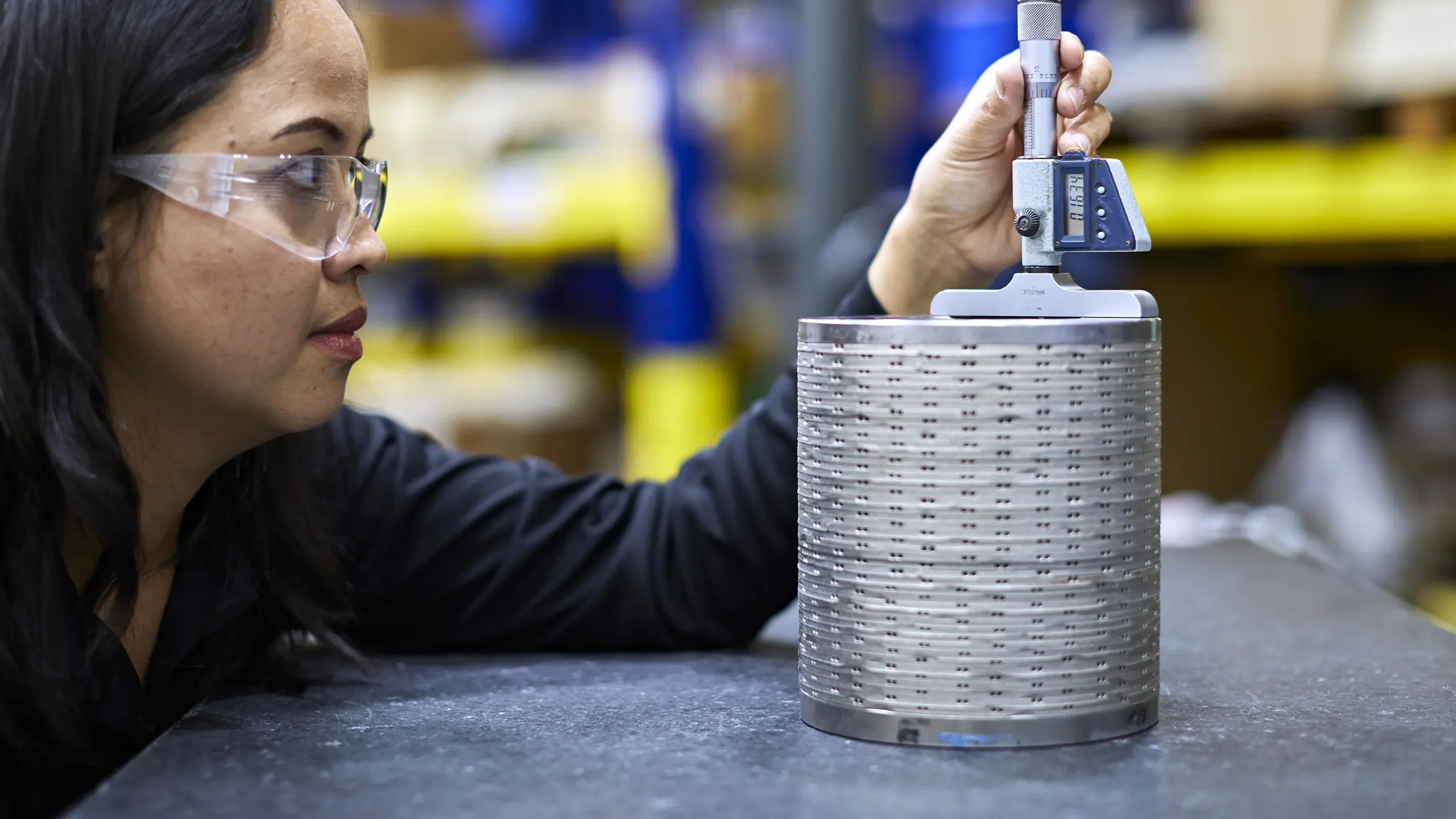

Retrofit3D

Expensive plant maintenance periods can cost oil and gas facilities significant amounts of revenue. Our Retrofit3D valve trim replacement solution can repair and improve critical control valves without removing or replacing them, while maximising valve performance and minimising maintenance costs. Making use of cutting-edge additive manufacturing we create customised valve cages and trims that deal effectively with damage or erosion issues.

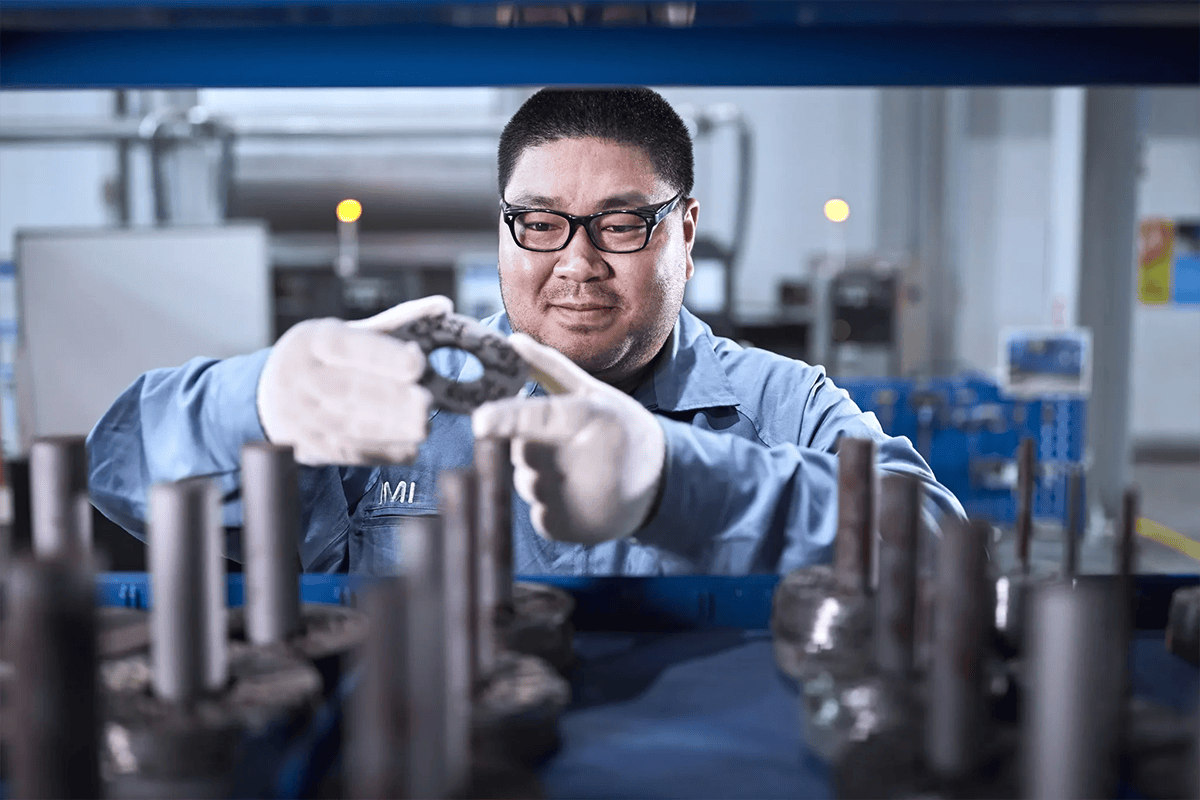

Metamorphic Trim

With oil and gas production plants facing constant problems with valve clogging, minimum flow control issues as well as poor rangeability we understand the need to resolve such problems at source. Our EroSolve Metamorphic Trim can successfully deal with particle contamination and flow issues to maintain productivity and profitability, unlocking full plant potential.

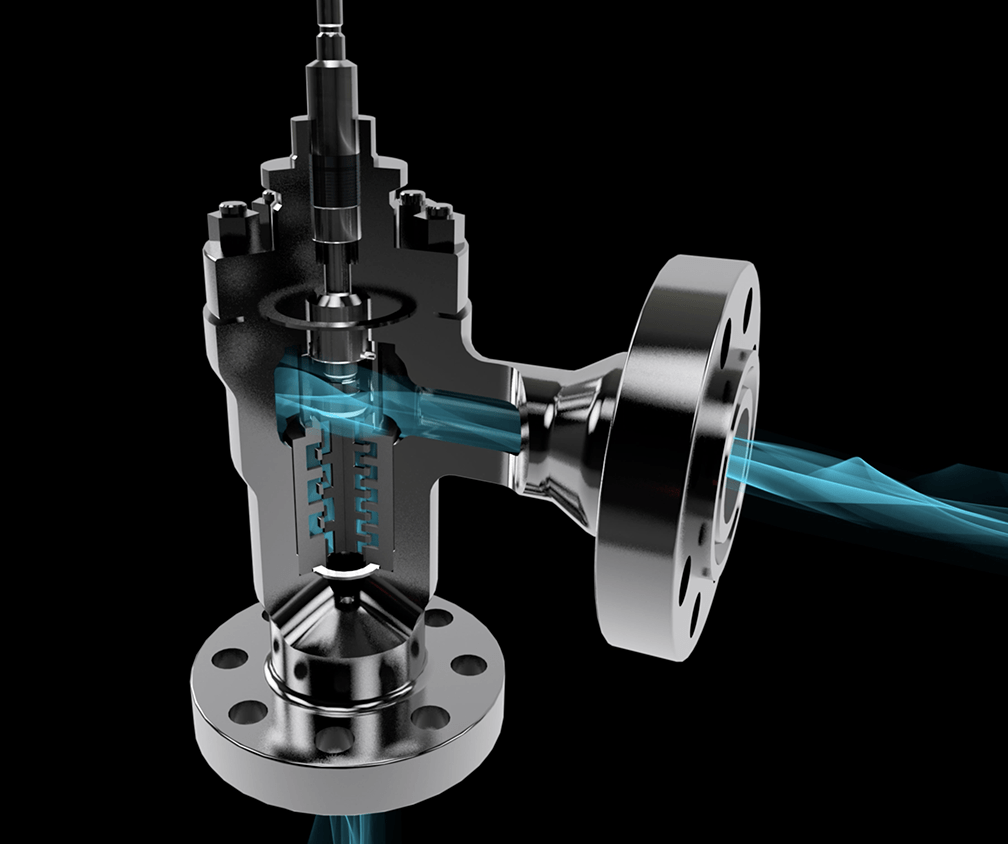

Flashing solution

Linear control valves often control liquids at extremely high pressure. As liquids pass through the constricted passages of control valves, they may experience flashing as the absolute pressure falls below the vapour pressure of the substance causing it to boil. Our EroSolve Flashing solution reduces valve erosion and maximises valve performance under such conditions, and is available for both existing and new production facilities.

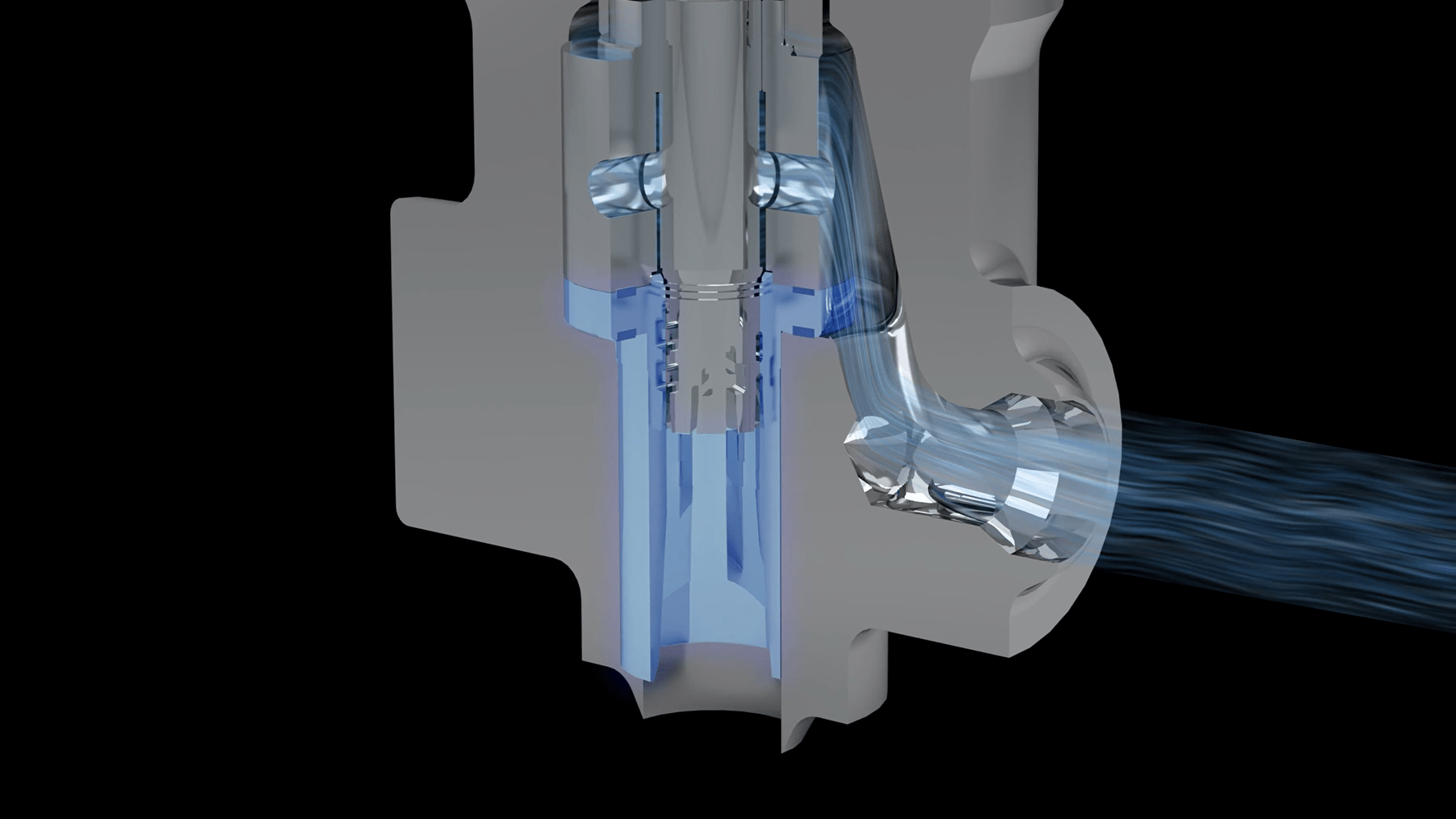

Wet steam solution

Flashed condensate or wet steam flowing at high velocity inside a valve can generate droplet impingement on trim and seat sealing surfaces that cause trim erosion and steam leakage. IMI’s EroSolve Wet Steam is a proven solution for tackling condensate or wet steam erosion and can be used in coal fired, combined cycle, combined heat and power and process plants.

Discover