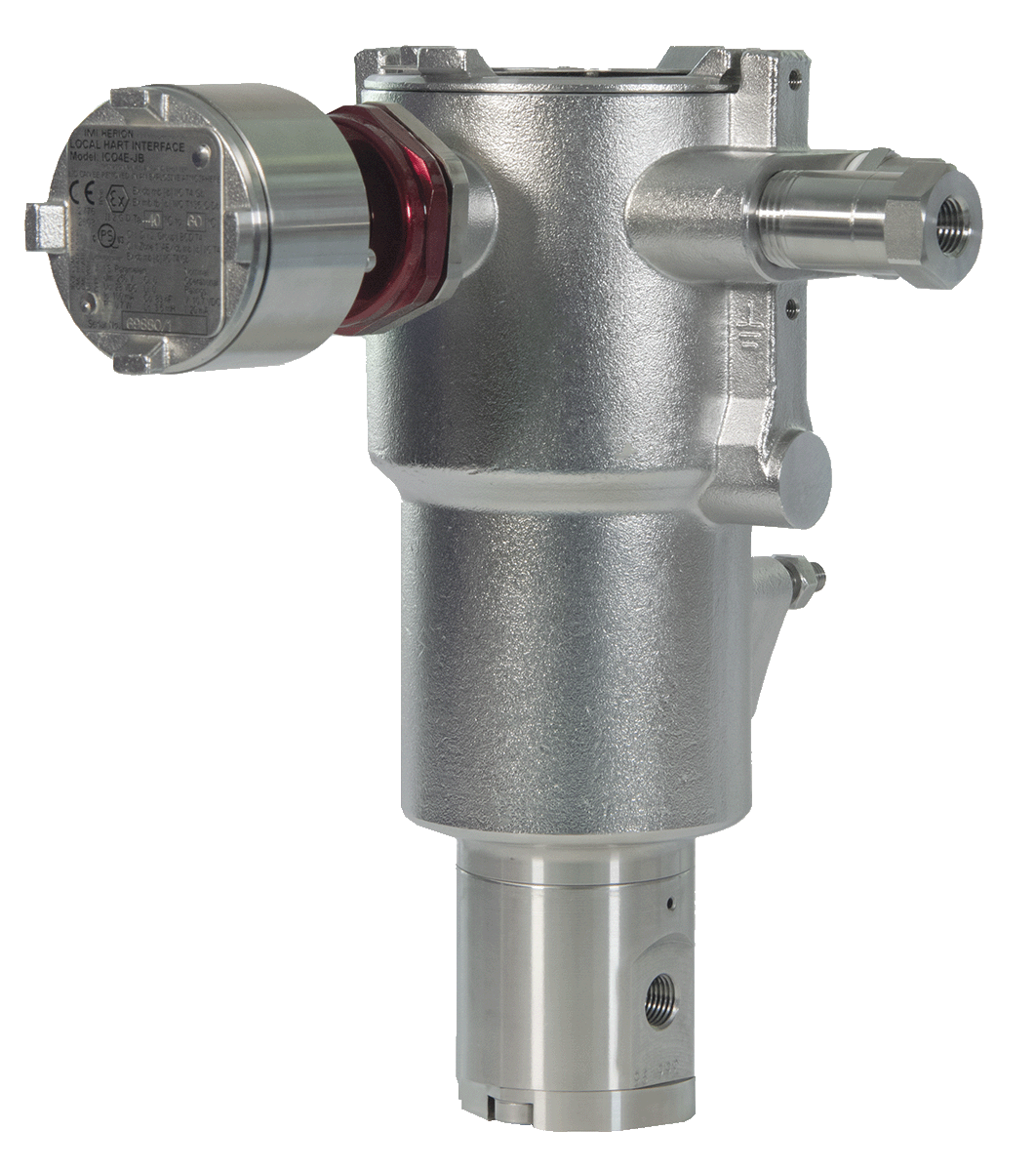

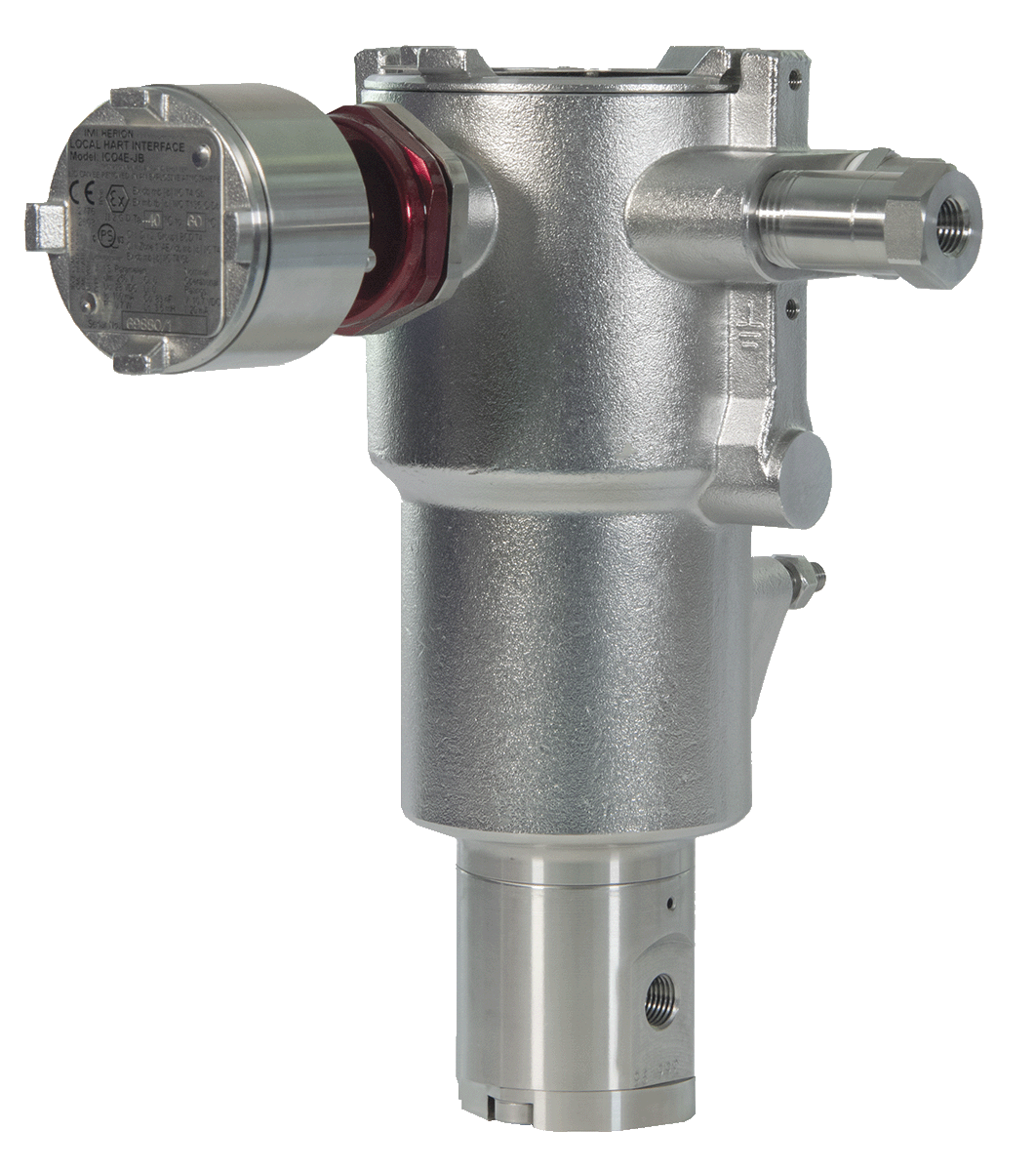

ICO4-PST Maxseal Smart Solenoid Valve

Maxseal direct acting solenoid valve for control of pneumatic or hydraulic operated equipment with partial stroke testing functionality

The Maxseal brand offers extremely high quality stainless steel solenoid valves designed and manufactured with reliability and integrity in mind. Maxseal valves perform exceptionally well in harsh environments all over the globe and are often associated with offshore oil & gas applications, but are also used onshore, particularly in coastal environments where a fully stainless steel construction is advantageous.

The ICO4S series has global certifications, and due to their exceptional reliability are often found on Safety Instrumented Systems. The ICO4S is in operation in both upstream and downstream solutions and has been the industry standard in air control and pneumatic switching for Oil & Gas, Petrochemical and Refinery applications for over 20 years.

The ICO4S Maxseal solenoid operated valve is a 2/2, 3/2 or 5/2-Way direct acting poppet valve where the line media is applied to the inlet port A. When power is applied to the solenoid, the valve opens and there is flow to the outlet port B. When the power is removed, the spring closes the valve and the valve exhausts through port C.

Our latest addition to the range, is the ISO4-PST which allows the operator to address all the requirements of partial stroke testing without compromise.

Key features:

- High performance solenoid valve with integrated partial stroke testing (Control of pneumatic or hydraulic operated equipment)

- PST operates final elements in identical manner to a shutdown

- Port Size: 1/4”….3/4” (ISO G / NPT) or manifold. Compatible with QEVs and POVs for very fast closing valves

- Environmental protection: NEMA 4X, IP66/67

- Certifications: ATEX, IN-METRO

Product Specifications

Body material

- Stainless Steel 316L

- Aluminium Bronze (NES 833 PT2)

- Titanium Monel

- Ferralium 255 – SD50 (Super Duplex)

- Hastelloy C276 (UNS10276)

Trim material

- Stainless Steel 316L

- Aluminium Bronze (NES 833 PT2)

- Titanium Monel

- Ferralium 255 – SD50 (Super Duplex)

- Hastelloy C276 (UNS10276)

Operating pressures

- 0-20 Bar

- 0-300 Bar

- 0-207 Bar

- 0-414 Bar

Nominal bore size & female thread

- 1/4″ NPT (6mm)

- 1/4″ BSPP (6mm)

- 1/2″ NPT (12mm)

- 1/2″ BSPP (12mm)

- 3/4″ NPT (20mm)

- 3/4″ BSPP (20mm)

- Namur Mount & 1/4″ NPT

- Namur Mount & 1/4″ BSPP

- Manifold Mount Face

Conduit entry

- M20 x 1.5mm ISO (F)

- 1/2″ NPT (F)

Temperature range

- Media: Minus 20 Degrees C to +60 Degrees C (Minus 4 Degrees F to +140 Degrees F)

- Ambient: Minus 60 Degrees C to +60Degrees C

Seat/seal material

- Nitrile

- Viton

- Devlon/Nitrile

- Devlon/Viton

Mounting position

- Solenoid Vertical

Flow

- 0,28 Cv (11,5 Kv) to 4.5Cv (86,2 Kv)

Medium

- Hydraulic

- Pneumatic

Operation

- Automatic

- Push Button Manual Re-set

- Push Button Remote Reset

Number of ports

- 3/2 Universal

Voltage

- 24V DC

- 48/50V DC (48V)

- 115-125V DC

- 115-125V AC

Environmental protection

- NEMA 4X

- IP66/67

Coil housing

- Ex d

Certification

- ATEX

- IECEx

- IN-METRO

Find your perfect flow control solution