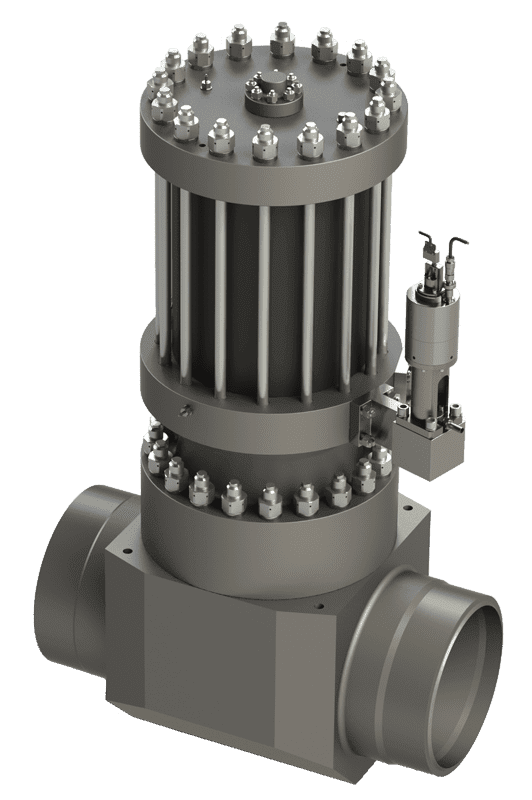

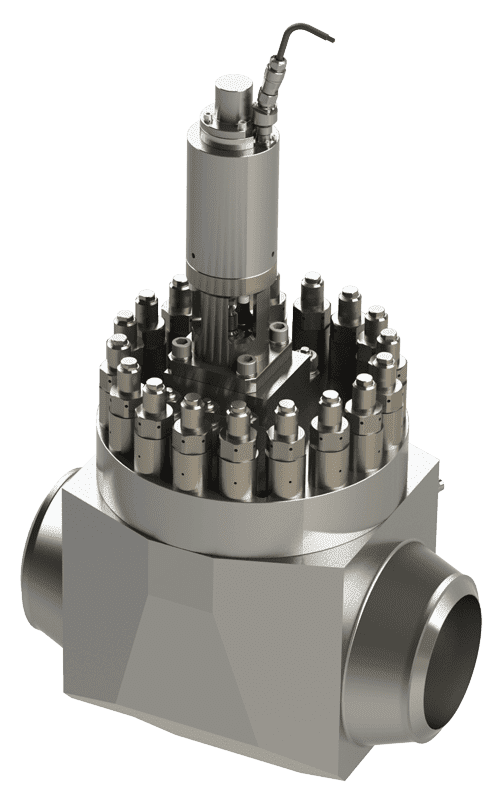

DAK Manifold Valve

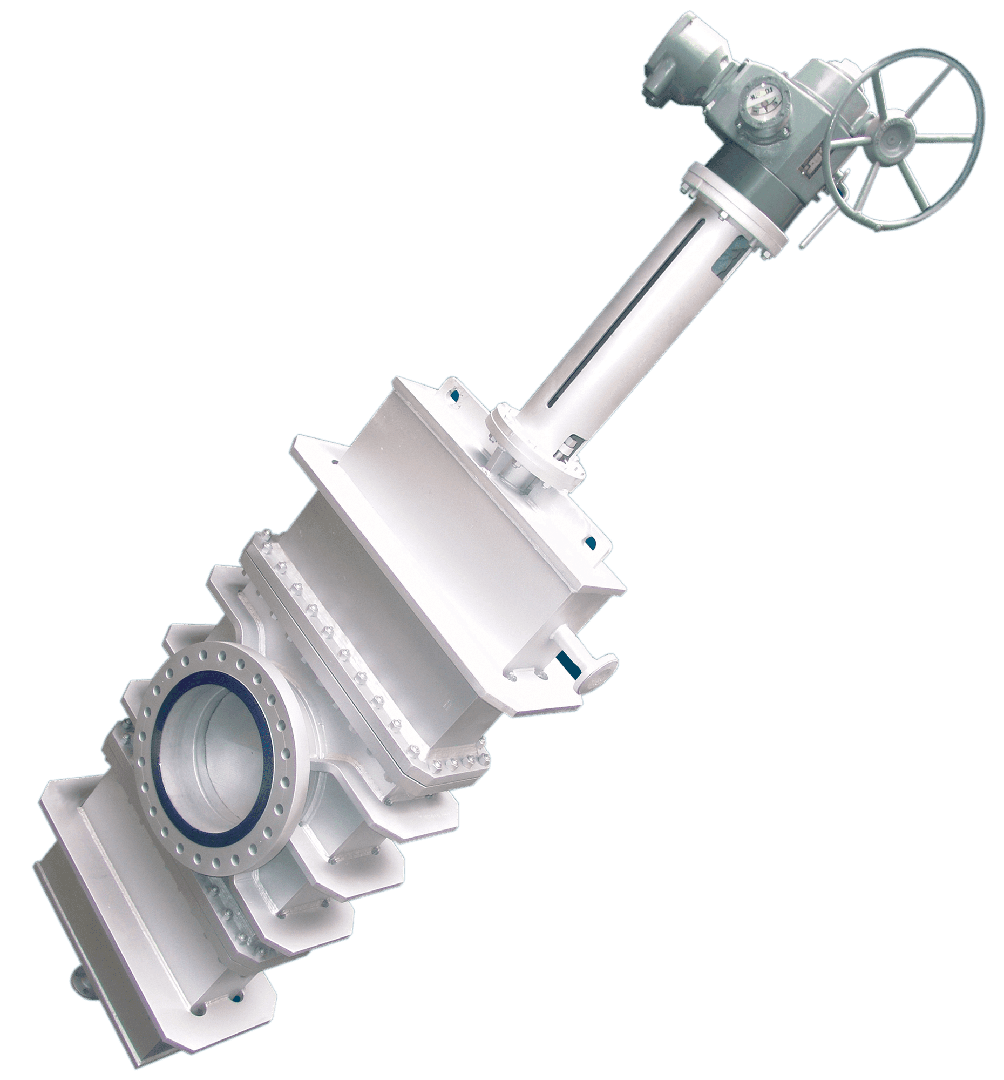

Gate valve replacement solution

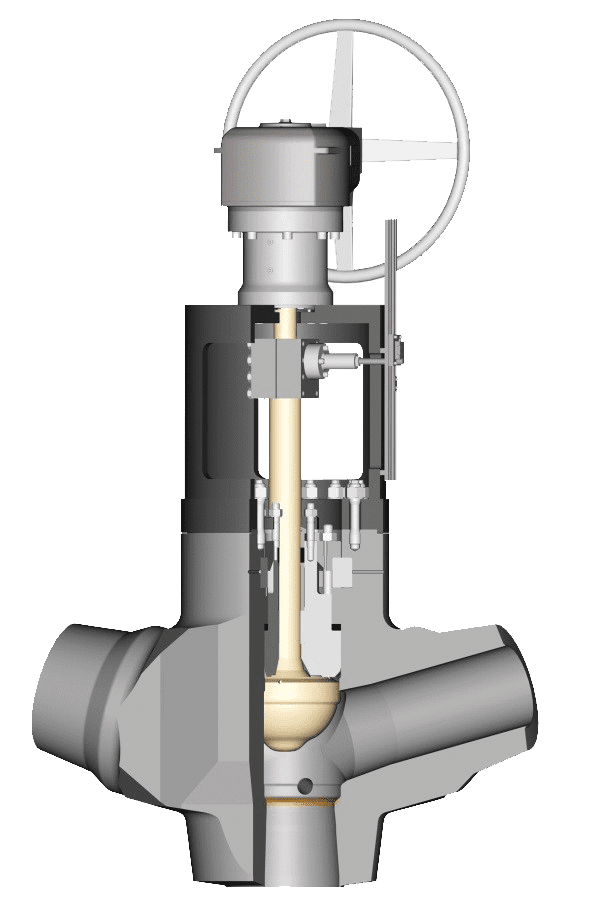

To ensure that large steam boilers are physically balanced and not subject to undue forces, the steam outlet piping is usually taken from both sides of the boiler and then brought together in a manifold to a central main steam line to the steam turbine. The pipes from the boiler are also usually equipped with manual gate valves which can be closed for pressure testing and/or maintenance. The DAK valve replaces these gate valves and the manifold to integrate all those functions in one single valve. The design of the valve also improves the steam flow reducing pressure drop and thus improves the overall efficiency of the plant.

- Simple operation.

- Monolithic body design to avoid weld joints.

- Excellent streamlining to reduce pressure drop across the valve and increase plant efficiency.

- Modular design of the valve to meet customer specifications and requirements.

- Inlet, outlet and bypass connections to match the dimensions and material of the pipework.

Product Specifications

Body style

- 2 inlets and 1 outlet, Y-shaped body

Operating limits

- Temperature up to 650ºC

- Inlet pressures up to 350 bar[a]

Interfaces

- Butt-weld ends according to the customer’s specification

Seat

- Hard faced seat

Bonnet

- Self-sealing bonnet

Actuator

- Manual, electric or hydraulic

Codes

- AD 2000, TRD, IBR, manufactured to ASME

Find your perfect flow control solution