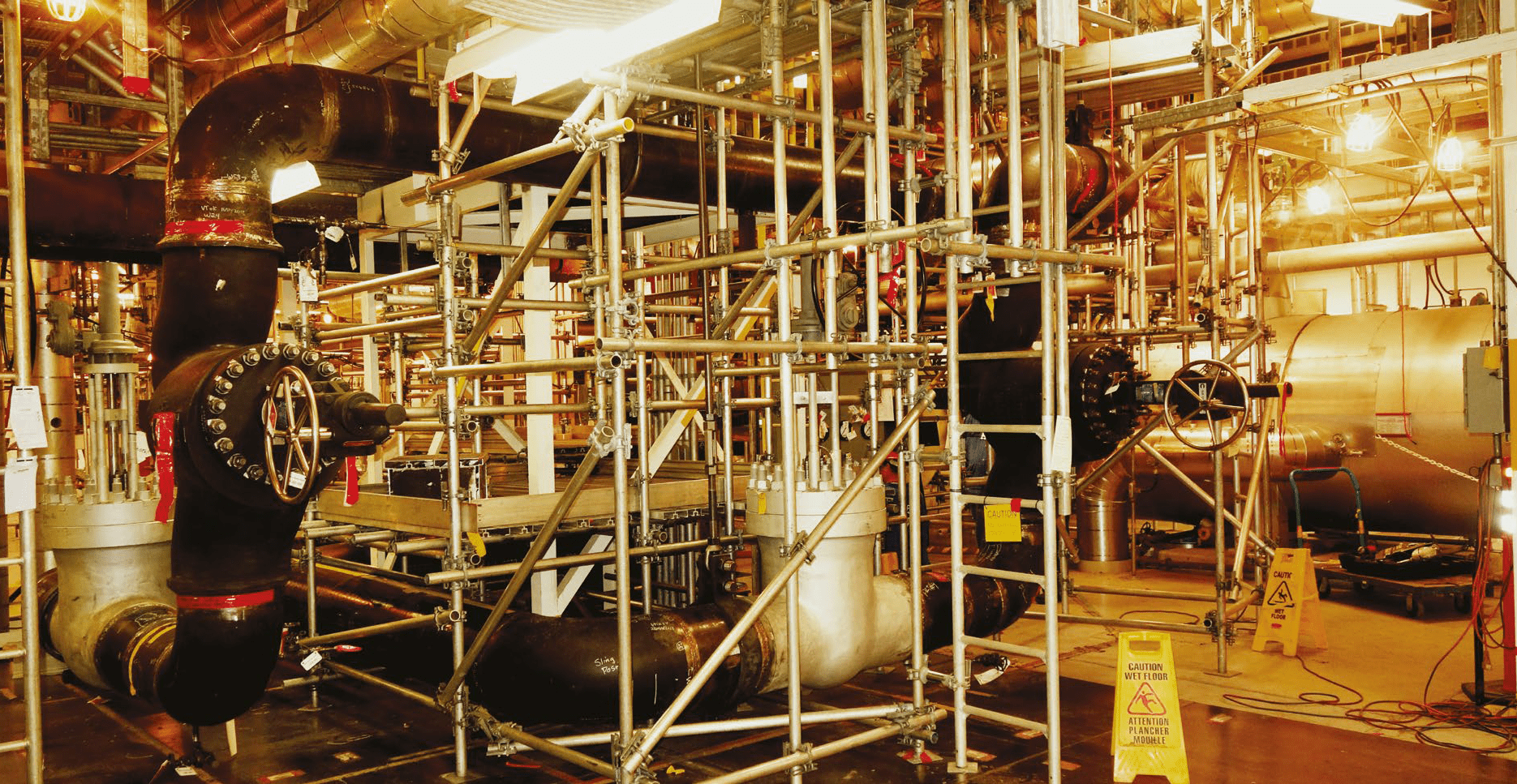

IMI CCI’s nuclear customer in Canada is currently refurbishing six of their eight CANDU type 779-817 MW reactors. One of the unique issues is tube wall thinning in the high-pressure heat exchangers. As the tube walls become thinner in a shell and tube heat exchanger design, the outlet temperature of the main feedwater increases. Over time, the slight temperature rise will shorten the life of the steam generator. As the customer plans the long-term replacement of the heat exchangers, a feedwater bypass line will be added to slightly reduce the heat exchanger outlet temperature and prolong the life of the steam generator. To modulate the bypass flow, a robust control valve is required. The valve would modulate flow with a very low pressure drop. Since the bypass piping is temporary and the valve stem will be horizontal, weight is a key factor in valve selection criteria.

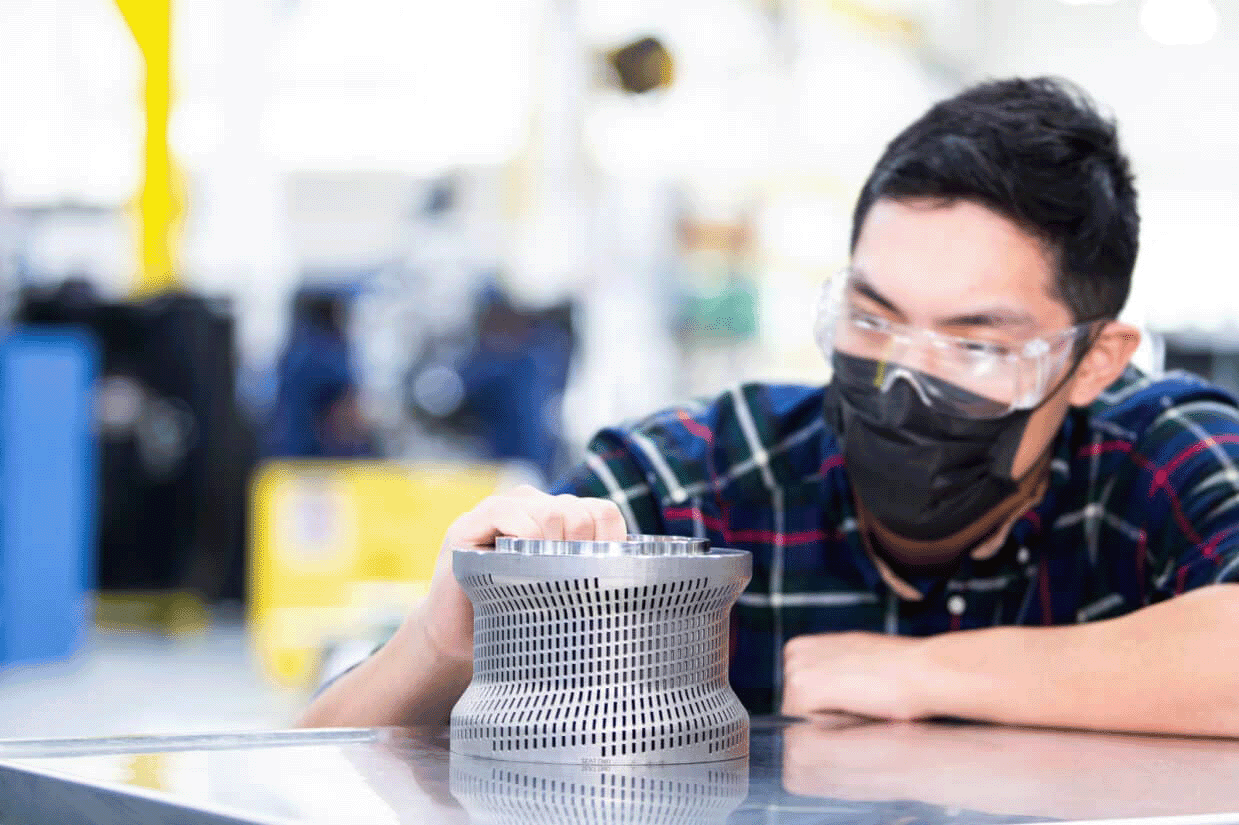

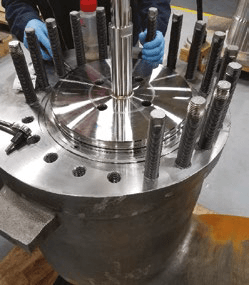

Assembly showing piston rings on plug.

IMI CCI proposed a manual operated 16” globe valve with a 14” trim for low pressure drop. The globe valve body proposed is 600# pressure class as cast, for minimum weight. The valve trim is a single cage component. This makes horizontal installation and disassembly easier than bolting together a seat ring, cage, guide bushing, and bonnet spacer. The plug has two piston rings and a guide ring for alignment in the valve trim. Trim alignment will be critical for a horizontal stem installation.

The valve stroke is only 5 inches, but the gear operator rotates 100 times per inch, allowing fine adjustment. The gear operator was supplied with a lock to set the valve in throttling position and make flow adjustments as needed. The valves were expedited to support a spring outage. Similar valves are expected to be installed at three other units.