After the addition of a new steam turbine, a European based pulp and paper plant performed a hazard and operability study (HAZOP) to ensure plant safety. Two key outcomes from this audit were SIL2 risk reduction requirements for certain critical valves and the need for active temperature control of steam during startup. This required desuperheaters and bypass stations that could handle a huge rangeability and perform effectively at low flows (velocities less than 5 m/s).

Given the significance of the changes, as well as the number of new valves and desuperheaters required to satisfy these requirements, the plant opted to look beyond their existing suppliers.

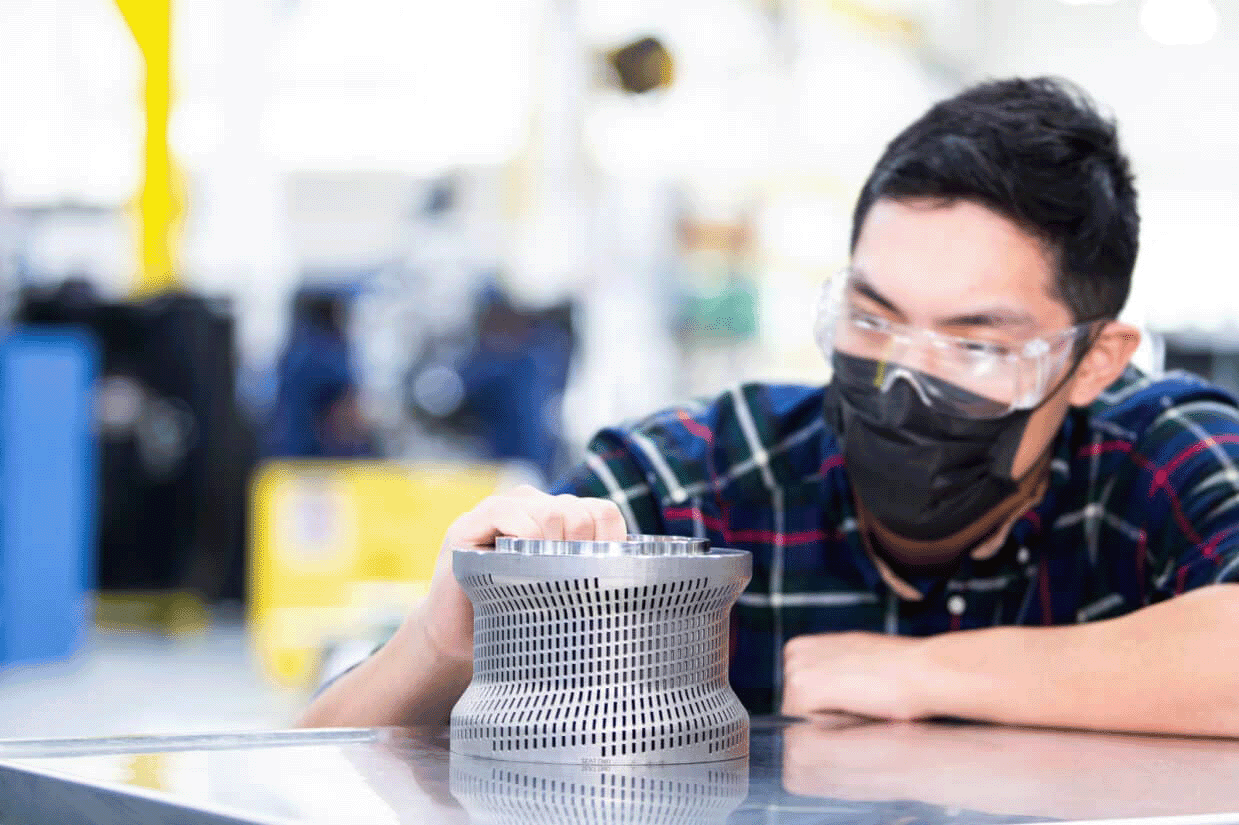

Standard VLB steam conditioning valve

Once alerted to the client’s need, the IMI CCI team initiated a detailed analysis to define the plant requirements. Based on multiple site visits to fully understand the various challenges, the IMI CCI team proposed a solution to the desuperheating challenge which combined normal water injection at high flows and steam assisted injection at low flows. Drawing from extensive experience and the long track record of their BTG technology, IMI CCI proposed the VLB valve with DA90-SE desuperheaters for the process bypass stations and several standalone DA90-SE attemperators for process desuperheating.

Beyond the desuperheaters, IMI CCI provided a complete package solution with HYDAC hydraulic units, safety valve technology from IMI Bopp and Reuther, and additional fluid flow analysis to support the client’s system process design.

With the high rangeability provided by the IMI CCI supplied hardware, the customer has gained flexibility in terms of operation, not only for startup, but also for partial loads. This operational flexibility will improve the pulp and paper output and generate more revenue for the customer!