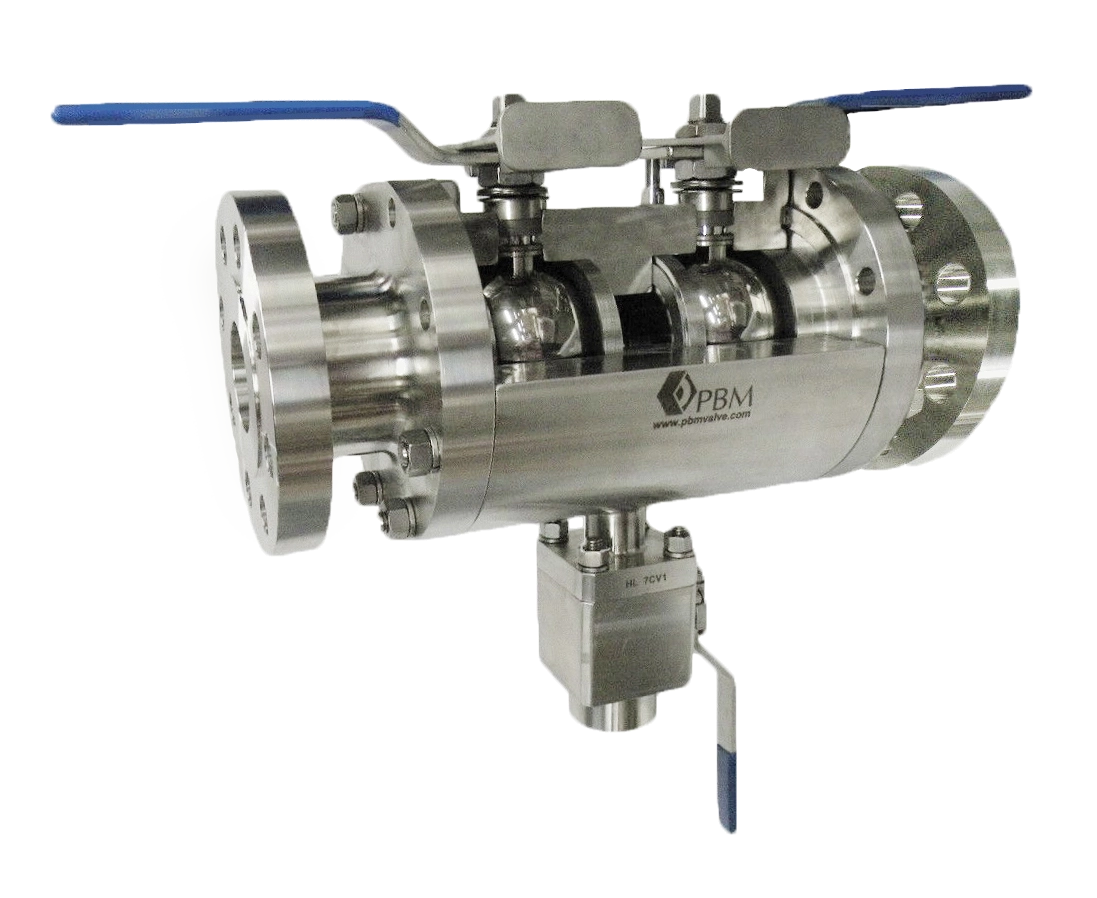

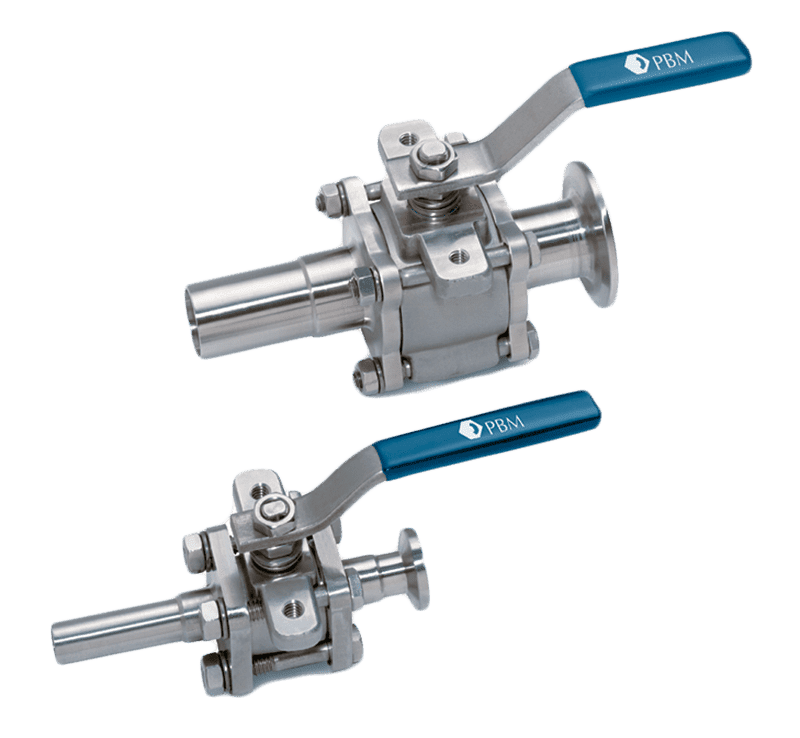

Instrument Valves

IM Series, Sizes 1/2” – 2”

IMI PBM’s Instrument valves are used for process flow or isolation of pressure gauge, orifice plates, flush rings and various measurement instruments. Valves are designed to ASME B16.34. They offer a higher performance solution to needle valves.

- Used for process isolation of isolation of pressure gauges, orifice plates, flush rings and various measurement instruments.

- IM Series Instrument valves DO NOT have o-rings.

- Designed to ASME B16.34.

- Tested to API-607 Fire Rated.

- Higher performance solution to needle valves.

- Can comply with API-6D if specified.

- Testing and Documentation – Material test reports, PMI, LP, radiographic examination, pressure testing per API598, Magnetic particle examination, ultrasonic examination.

- Certified SIL-3 capable per IEC 61503.

- Certified to API-622/API-641.

Product Specifications

Sizes

- 1/2” and 3/4” up to ANSI class 2500 (CL 1500 standard)

Material

- 316 Stainless Steel

- Hastelloys Duplex SS

- Carbon Steels

- Monel or others

Temperatures

- From 350°F to ?800°F depending on material

End connections

- Thread pipe

- Buttweld

- Socket weld

- Compression

- Instrument adapter flange

Seats & seals

- C-TEF™

- V-TEF™

- S-TEF®

- PEEK®

- Stellite

- Tungsten or Chrome Carbide

- coated S/S ball/seats

Stem packing material

- Die molded graphite V-TEF™

- C-TEF™ or S-TEF®

- API-622 Low-E Stem Packing Standard in 1/2” and 3/4” sizes with .41 bore. It is optional in larger sizes.

Maximum working pressure

- Maximum CWP depending on seating and valve material of construction

Find your perfect flow control solution