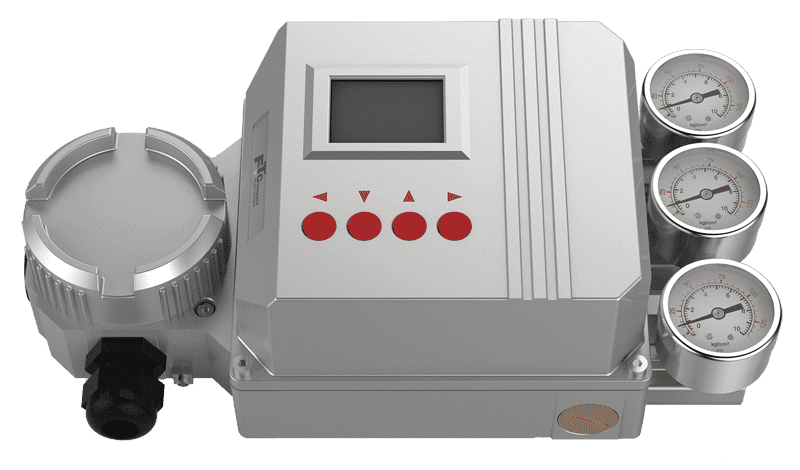

FasTrak Smart Digital Valve Positioner

Smart positioner with high-capacity, high-precision digital-pneumatic valve controller

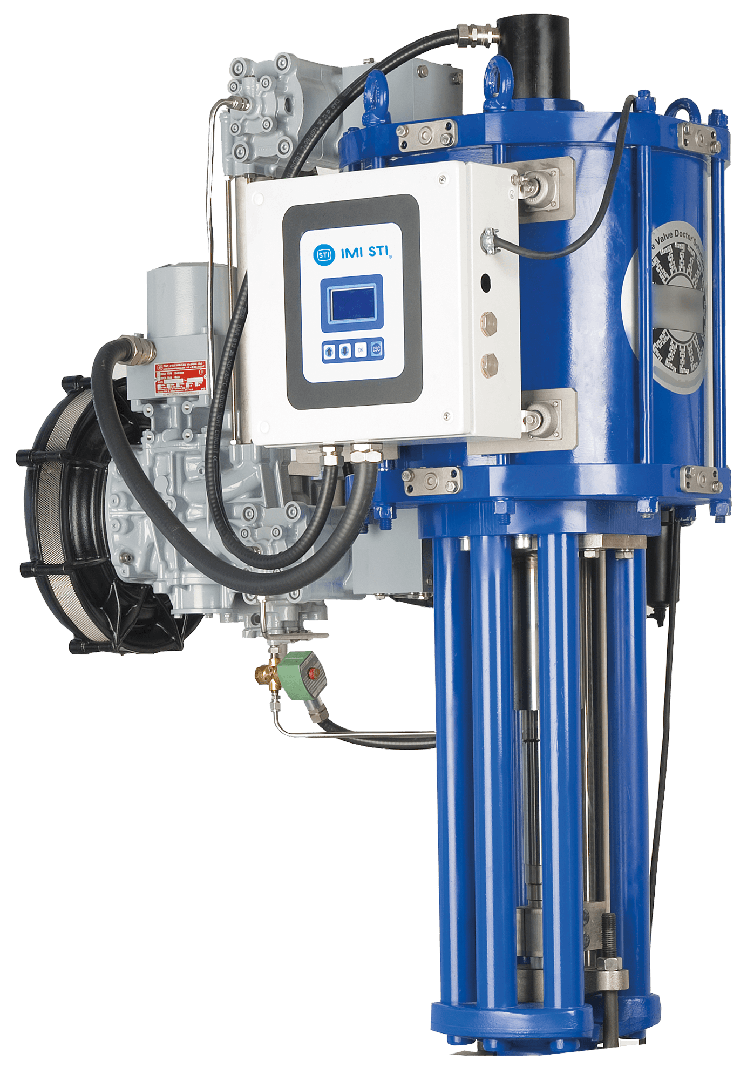

FasTrak is a high-capacity, high-precision digital-pneumatic valve controller that replaces a conventional positioner. It has an excellent dynamic performance and high flow (Cv = 2). Configuration and calibration is carried out with a HARTTM device or by self calibration. FasTrak is compatible with double and single acting actuators, with or without a spring, a piston or a diaphragm.

- High Flow Precision Control-The unique design allows high speed performance in large volume actuators without additional amplification (e.g. Booster or quick exhaust).

- Control Algorithms & Hardware-Self calibration on double acting piston, diaphragm, rotary actuator with or without spring; patented adjustable independent control parameter to open and close stroke.

- Strong Shaft Design-Not sensitive to radial and axial external load caused by mounting and linkages.

- Environmental Protection-The IP66 protection and unique exhaust protection system makes it suitable to be installed in harsh environments where there is tropical rain, dust, sand, salt.

- Embedded Features – 4-20 mA position feedback, digital inputs for configurable trips, digital outputs configurable for limit switches and/or alarm.

- Communications – 4-20 mA control and power with HART™ communication protocol with high speed serial connection.

- Software Interface-Dedicated software (RCFT) to set, customize, control and monitor high dynamic performance.

- CE EUROPEAN DIRECTIVE

- Intrinsically safe (Ex ia) / Explosion proof (Ex d [ia]) according to:ATEX, IECEX, CSA/cUS,CUT, INMETRO.

Product Specifications

Connection

- Power:2 wire from signal (min 3.5 mA, 10/30 Vdc)

- Electrical connections:Input signal M20x1.5,Auxiliary output position feedback,M20x1.5

- Pneumatic connections:¼” NPT female

Input

- Signal:4-20 mA with HARTTM protocol Configurable split range

- Communication protocol:HARTTM protocol,Local display,TTL RS232

Output

- Position:4-20 mA passive loop

Stroke Movement

- Feedback angle of rotation:30º/90º (<30º with lower resolution)

- Adjustable speed:Range 0/300 seconds, individually configurable for each direction

- Characteristic curve:Linear,Equal percentage,Configurable by user

- Control parameter:Individually configurable for each direction

- Travel control:Minimum and maximum settable stroke limits / cut off

- Signal fail:End stroke limits (4 mA position)

Air Supply

- Instrument air:Free of oil, water and dust to ISO 8573-1 – Class 3

- Supply pressure:1.4÷7 bar

- Air consumption:1.5 Nm3/h at 6 bar

Performance Data

- Hysteresis + deadband: ±0.5%

- Repeatibility: ±0.2%

- Sensitivity: ±0.1%

- Linearity: ±0.5%

- Influence of ambient temperature: 0.3% for every 10°C

- Air capacity: Up to 23 Nm3/h at 6 bar (CV 0.3)

Environmental Capabilities

- Ambient:Protection IP65,Operation temperature -40° to +80°C

- Humidity: Up to 100%

- CE mark: CE conformity and EMC

Materials

- Aluminium

- Stainless steel feedback shaft

Weight

- 2.30 kg (with 3 pressure gauges)

Find your perfect flow control solution