DAM Steam Desuperheater

Steam desuperheater

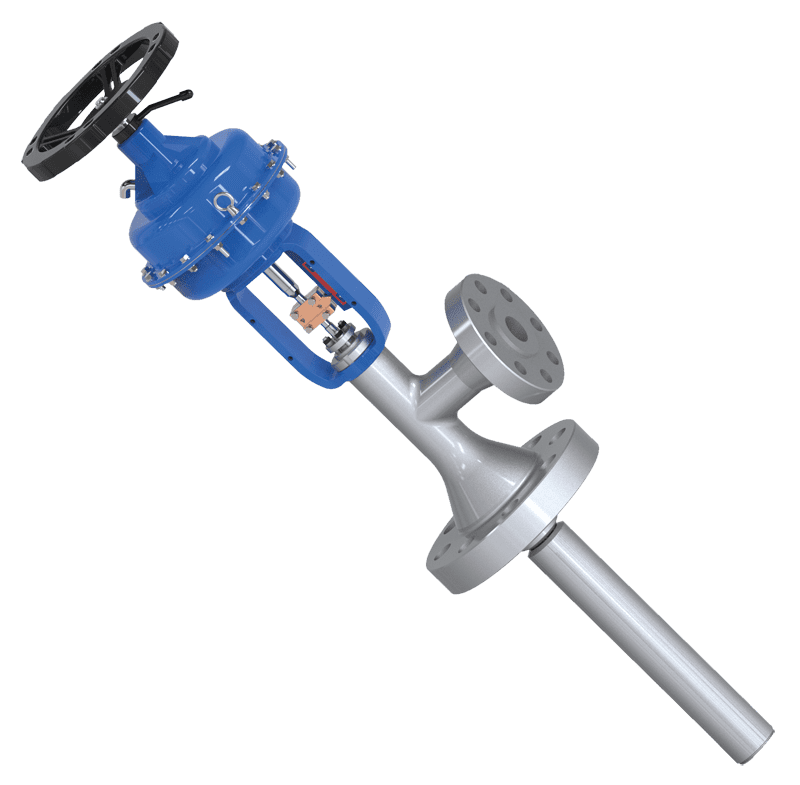

Desuperheating is used to improve the thermal efficiency of heat transfer processes by lowering the temperature of the steam to close to saturation temperature. The DAM steam desuperheater is used in applications where large spray water flow is required when desuperheating the steam, and where the demand for saturated steam is high. The DAM is a high performing ring style desuperheater with a welded flow profiling liner for superior evaporation and performance. It complies with all existing standards and is always pressure tested on both the steam side as well as the water side.

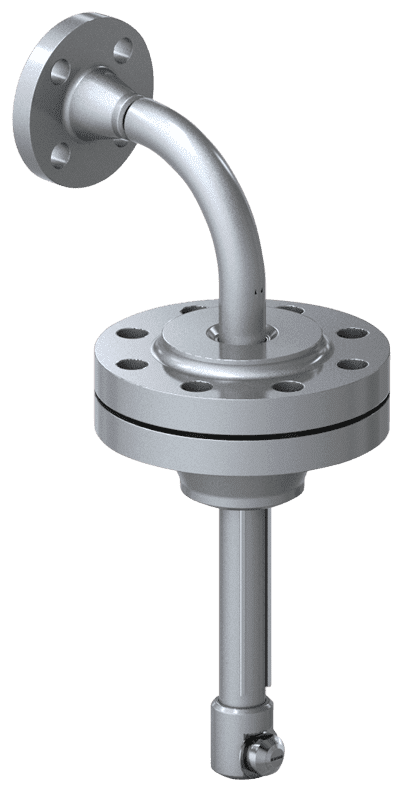

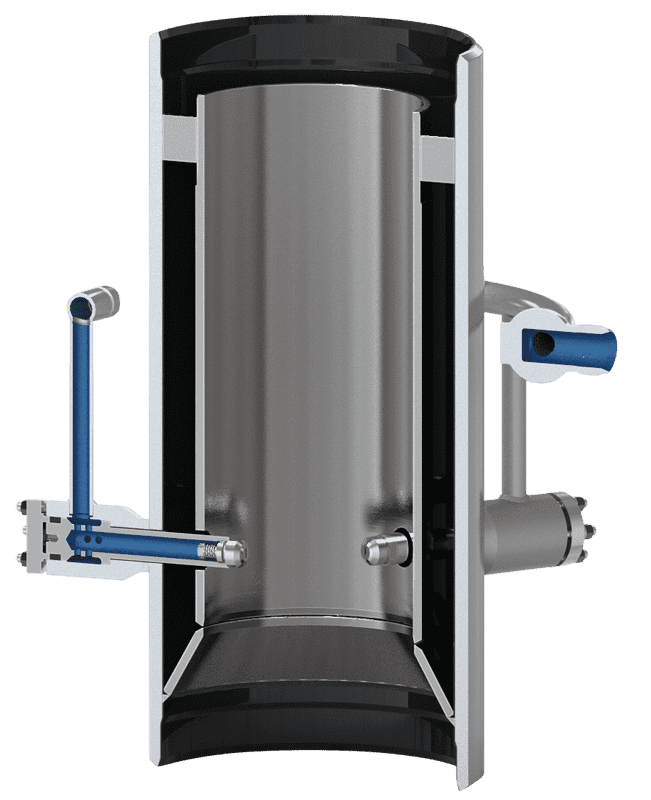

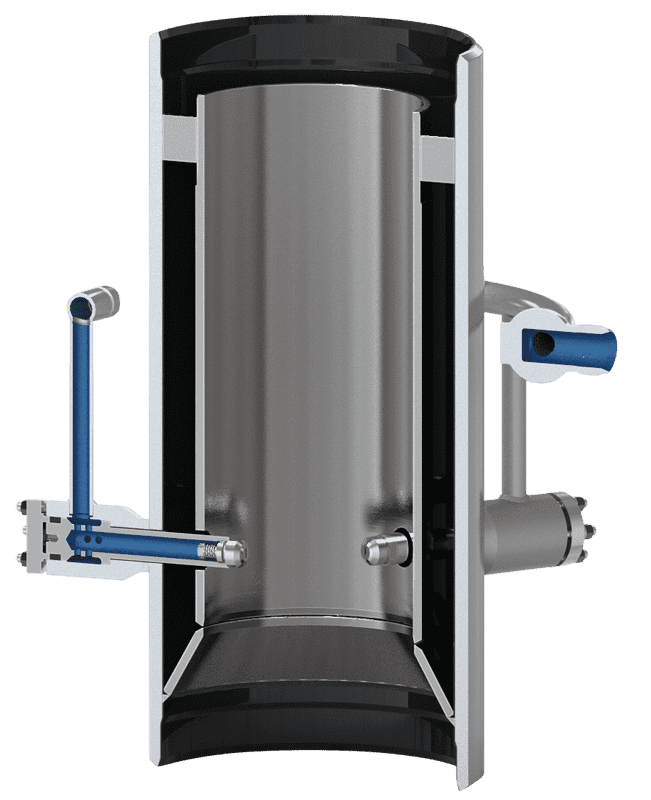

The DAM desuperheater is installed in the steam pipe with a number of water atomizing nozzles attached. The size of the nozzles, their number and insertion length may differ depending on steam desuperheating needs and steam pipe diameter.

The nozzles receive water from a common spray water pipe encircling the steam pipe, supplying water evenly across the nozzles.

Spray water flow is controlled via an external spray water valve connected to the DAM water connection piece. This valve is regulated via a temperature control system that uses the downstream steam temperature to determine the amount of spray water needed. The placement of the temperature transmitter and the installation of the steam pipe are of critical importance for achieving accurate steam temperature regulation. For more information, see IMI CCI document ‘II500.11 – System design considerations for DAM desuperheaters’.

A flow profiling liner is welded to the inside of the DAM body to improve system turndown and to protect the steam pipe against thermal shock and erosion in the downstream pipe.

Product Specifications

Capacity

- Unlimited (Depends on size and number of orifices)

Rangeability

- Nozzle turndown: Limited only by turndown of selected water control valve.

- System turndown: Minimum steam velocity depends on pressure, temperature and superheat, but should typically not be below 6-8 m/s (20-25 ft/s)

Materials

- Nozzle body: X19CrMoVNb11.1, AISI 616

- Plug: X19CrMoVNb11.1, AISI 616

- Spring: Heat resistant spring steel

- Adjustment nut: X20Cr13, AISI 420

- Steam pipe/ liner: 10CrM0910, A335-P22 liner or 14CrM044, A335- P11or St35.8, A105 or A-182 F91, X10CrM0VNb91

- Water pipes: 13CrM044, A335-P11 or St35.8 (A105)

Pressure class

- DIN PN 16-320

- ANSI 150-2500

Find your perfect flow control solution