A petrochemical complex in Saudi Arabia with a cracker unit that produces one million tons of ethylene per year was experiencing frequent body and trim erosion from a competitors’ boiler feedwater control valve. After repeated attempts, the competitor was unable to fix the issues. The IMI CCI upgrades team was on site when the existing competitor’s three inch, ANSI 1500 class main feedwater control valve was brought in for maintenance and witnessed the pin-hole erosion damage at the valve outlet. During discussions with the customer, the team understood that repeated maintenance of the trim and body resulted in the customer needing to periodically perform welding repairs to the body.

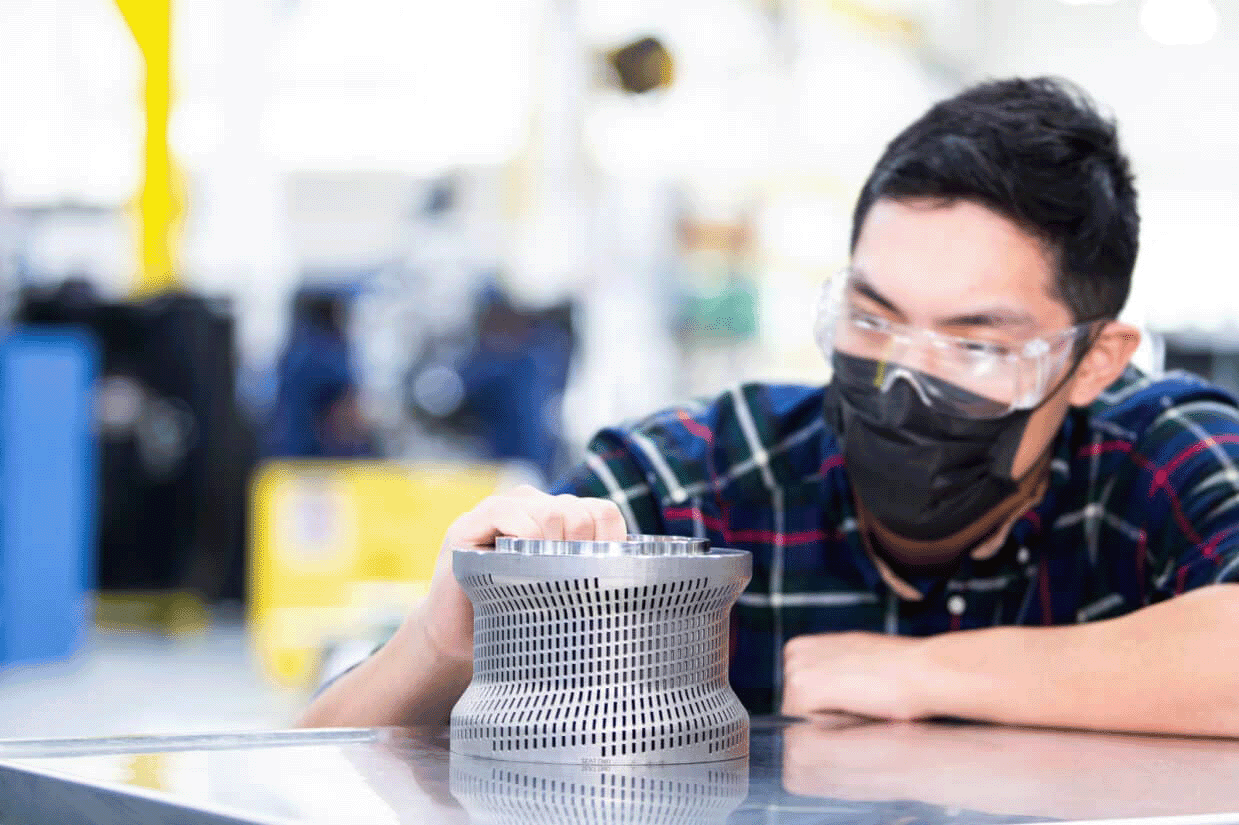

Detailed information was collected and an analysis was performed which led to the discovery that the existing valves were not suited to handle the actual operating conditions. The existing trim with drilled hole cage design generated 140m/s (459 ft/s) trim exit velocity at pressure drops of 140barg against ISA recommended trim exit velocity guidelines of 23 m/s (75 ft/s). The high trim exit velocity combined with cavitation is the main reason for the cage and body erosion.

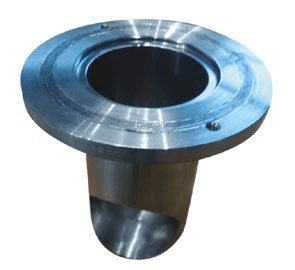

To eliminate this erosion problem in the application, the IMI CCI team offered the proven DRAG® technology trim design. This trim design has 12 pressure reducing stages to eliminate cavitation and limit trim exit velocity to less than 23m/s (75 ft/s) in the IMI CCI design valve. In addition, a removable seat basket was designed to go inside the valve body preventing any body erosion in the event of unforeseen flashing conditions. The team presented the solution in detail to the customer with references to thousands of successful installations around the world. The customer has placed an order to replace all eight competitor boiler feedwater regulator valves at this plant.