Our client’s paper mill is one of Europe’s leading manufacturers of pulp and paper. It produces high-quality office paper for printers and copiers; offset paper for reports, books, posters etc; coated paperboard for packaging; and newsprint made from 100% recycled waste paper.

The existing probe-style desuperheaters had been in operation for many years and the customer was looking for new equipment to improve steam temperature control.

The IMI CCI team worked with the customer’s engineering company to provide a significant amount of technical support to fully understand the customer’s requirements. The desuperheaters needed to provide steam to the process at a temperature close to saturation point. High reliability and precise temperature control were crucial for the application.

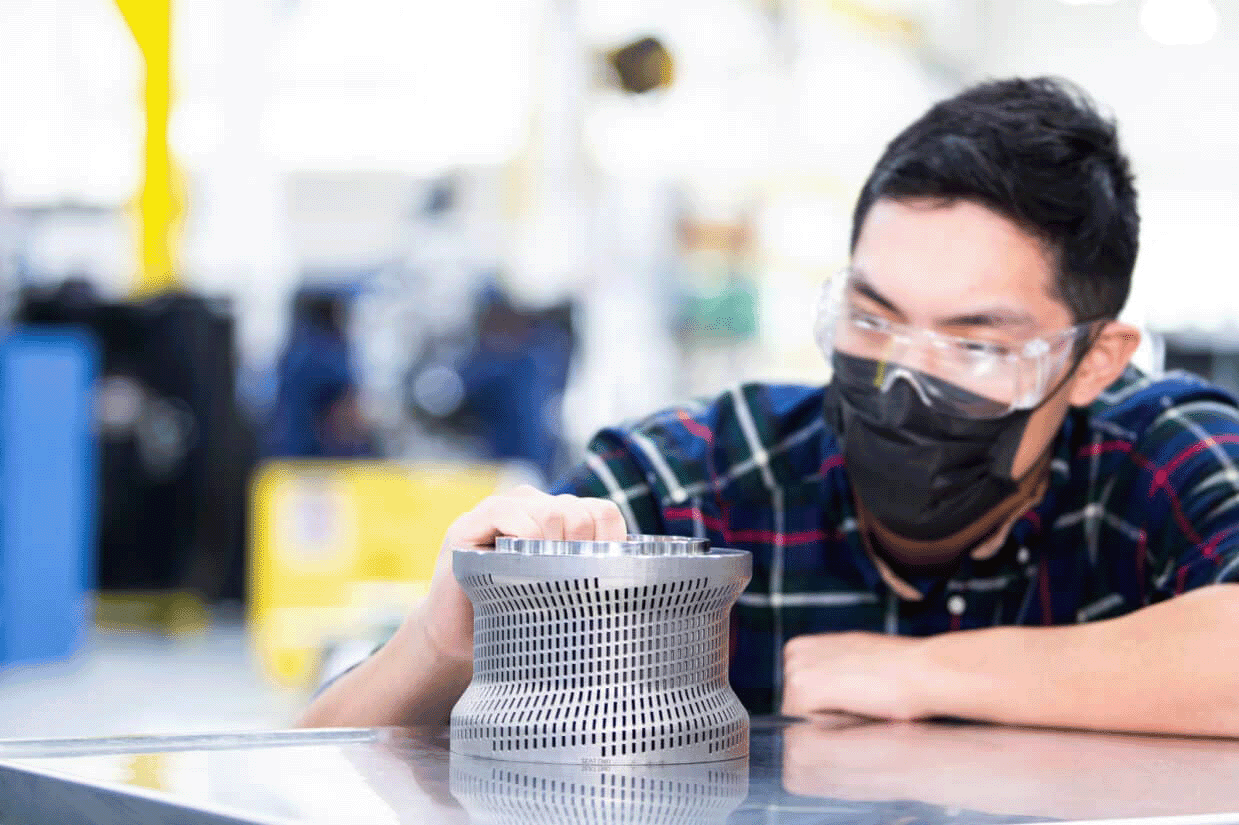

The DAM Desuperheater

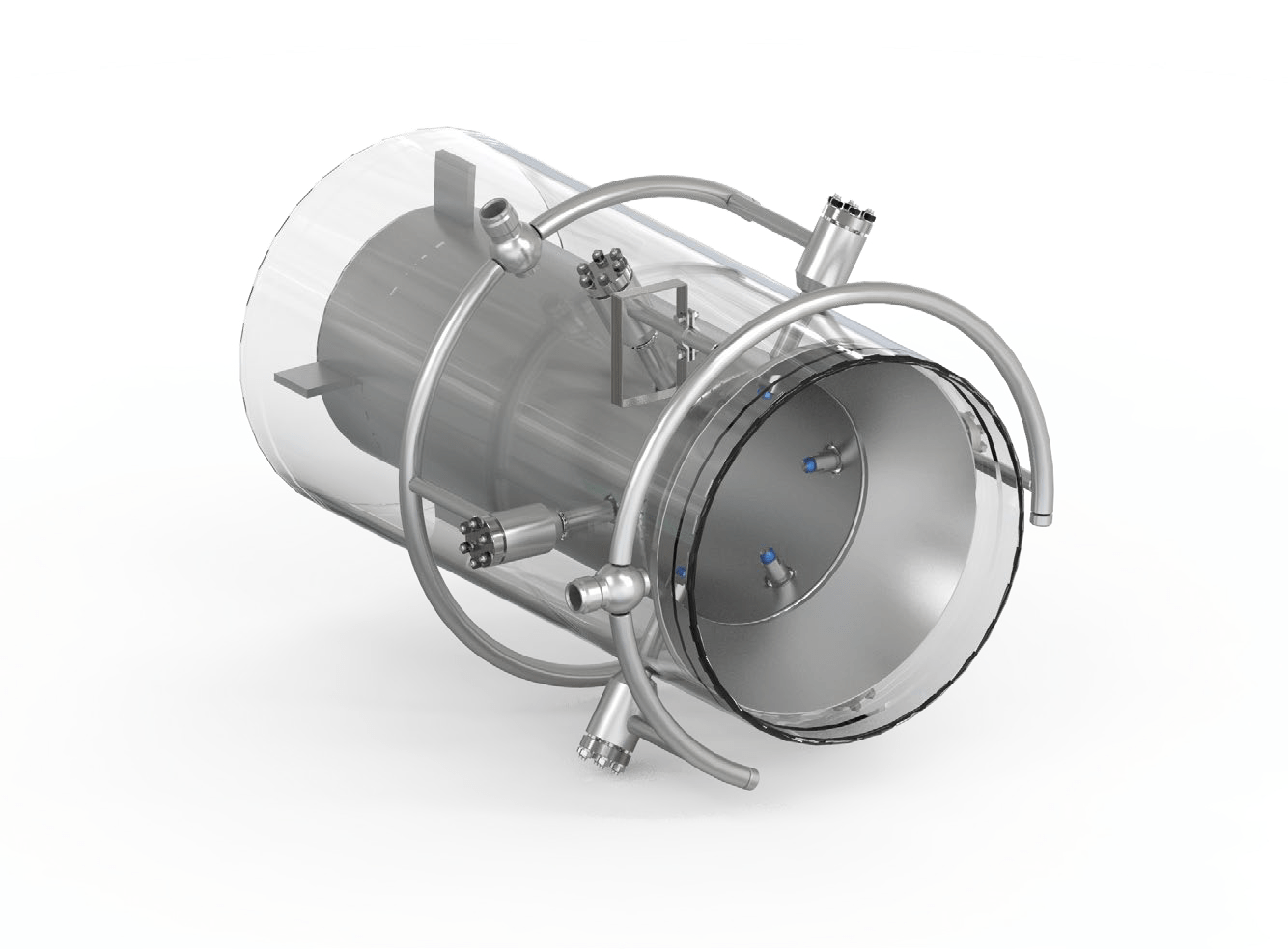

The team identified that due to the low steam velocity at low flow conditions a probe-style desuperheater would not sufficiently evaporate all the water injected in the system. IMI CCI proposed the DAM desuperheater with a flow profiling liner, allowing the water injection point to be adapted to optimise evaporation of the injected water. The liner increases the steam velocity at low flow conditions and creates turbulence at the liner exit to enhance mixing of steam and water droplets. The increased steam velocity and mixing enables the DAM desuperheater to provide reliable process steam at close to saturation temperature.

Since the downstream process steam requirement is critical, the DAM is equipped with two independent rows of nozzles, connected to two separate spray water control valves which ensure full redundancy on the system.

The IMI CCI Valve Doctor® support provided the customer with a detailed understanding of desuperheating systems and led to a continued relationship with the team at IMI CCI.