Several years back, IMI CCI supplied this power plant customer with eleven valves in three of its units. Apart from the soft goods kit, the customer had not purchased any parts, field service support, or repairs for several years. The IMI CCI sales team visited the plant and discovered that the plant was having issues with their existing high-pressure interstage attemperators and associated spraywater valves which was affecting their heat rate.

Detailed analysis of the service history of the installed equipment revealed use of a non-original equipment manufacturer (non-OEM) for parts and repair on the installed IMI CCI valves. They had also replaced the upstream isolation valve, which was now leaking, less than a year after installation. The customer purchased IMI CCI parts for the 100DSV spray valve but did not follow the team’s recommendation to use IMI CCI field service support to install the parts.

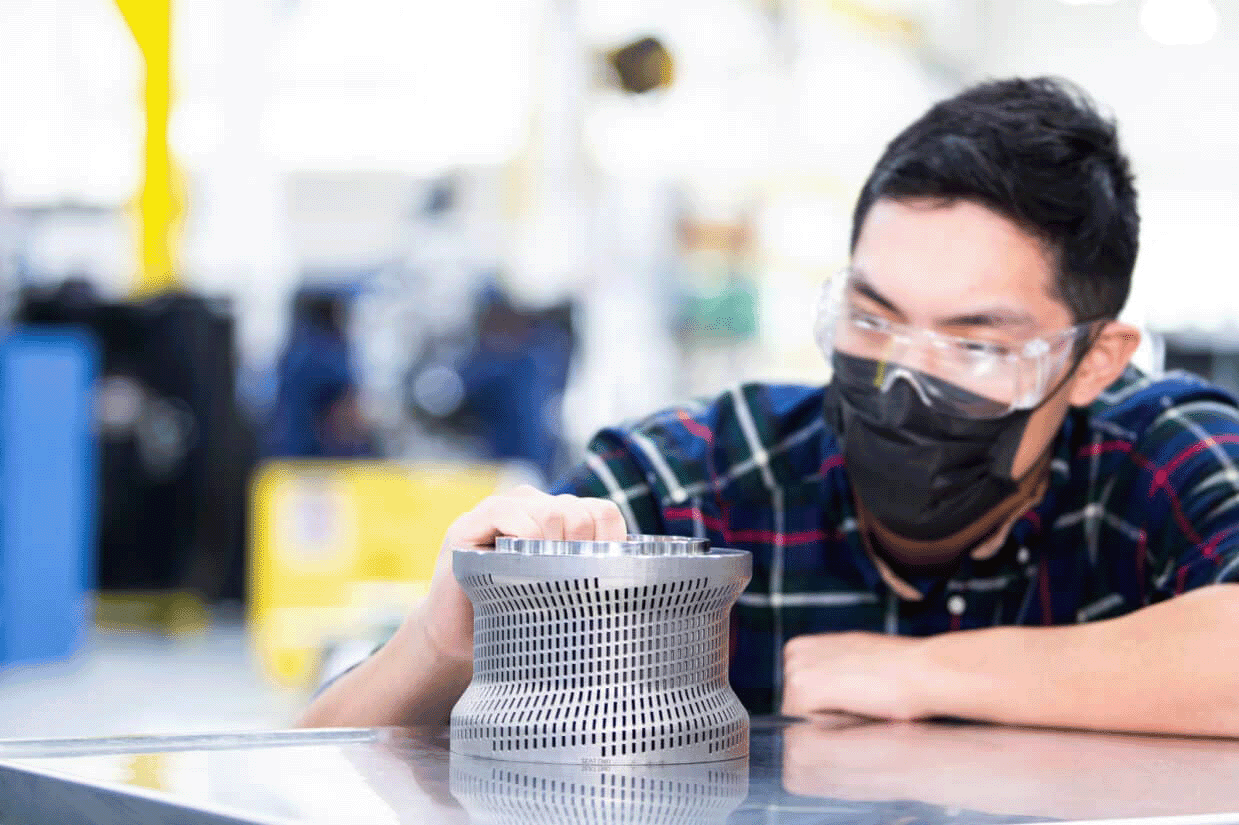

The IMI CCI Sales team was able to establish that the poor installation by the 3rd party of the IMI CCI trim was causing the valve leakage. IMI CCI was invited to submit a proposal for a complete asset management solution that included: preventative maintenance program, upgrade solutions, and service and repair on all IMI CCI installed assets in the plant. Based on our engineering expertise and ability to provide a complete asset management solution, the customer recognised the value brought by the original equipment manufacturer compared to a 3rd party service company.

The customer placed an order replacing all 3rd party parts in the plant and allowed IMI CCI to execute full-turn key field service followed by OEM repair. The customer discovered that saving a little money using non-OEM parts and service ended up being more costly in the long-term.