The American chemical company had a large number of IMI CCI DRAG® valves installed at its plant in the US. Many of the valves at the site were over 20 years old, but working to the satisfaction of the customer. IMI CCI and the customer agreed a complete review of all 19 of the installed assets at the plant to support the forthcoming plant shutdown. The Americas’ sales and service team worked together to review the 19 assets and identified 5 valves in need of a complete upgrade while the remaining 14 valves required a combination of repair and parts replacement to be performed at the Houston repair centre. The major challenge with the 5 upgrade valves was to meet the existing face to face dimensions of the original IMI CCI valves installed at site.

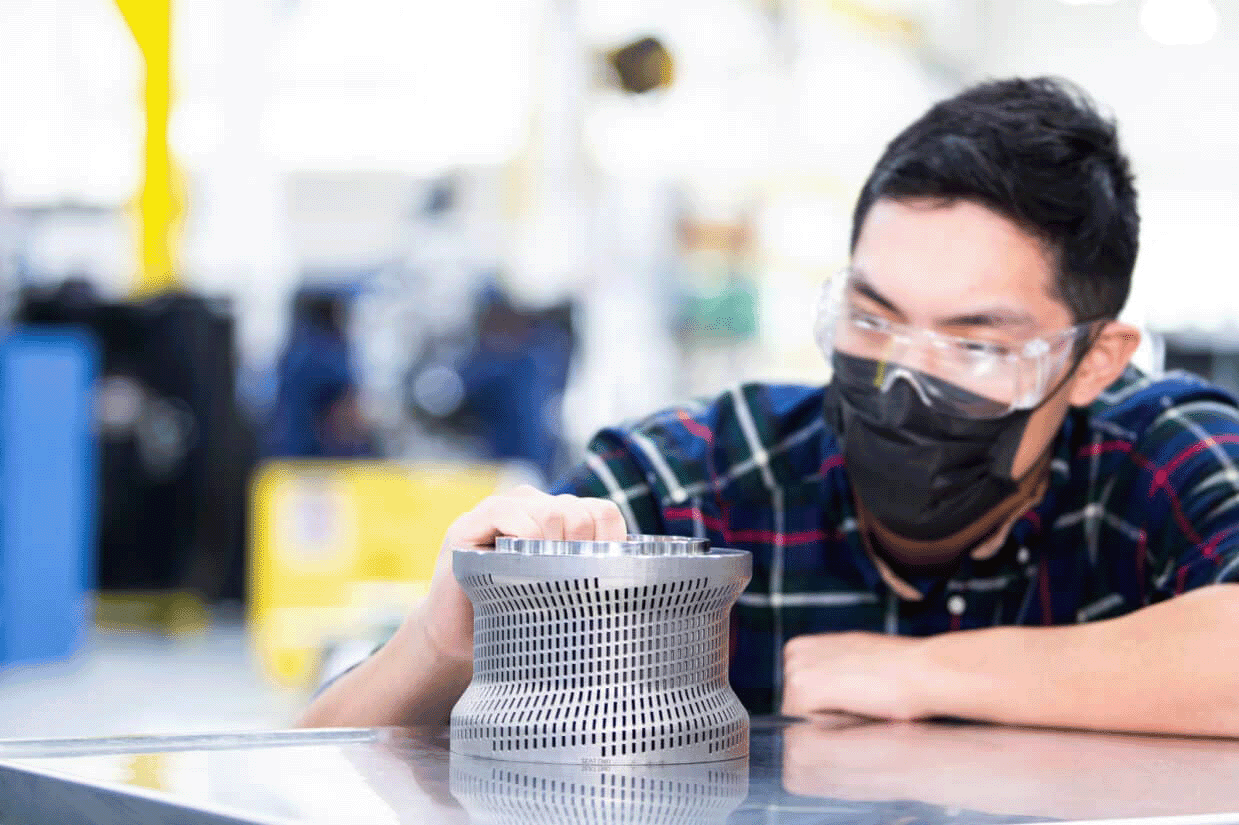

The IMI CCI team worked closely with the site to understand the actual process conditions and valve operation. Based on the information, new upgrade valves meeting the face to face dimensions were offered. These incorporated many design improvements, such as higher grade material, robust disk stack design with more accurate Cv and the new high endurance actuator. For the remaining 14 valves the team identified parts that needed to be replaced or repaired in order to make a final recommendation to the customer.

The site owner appreciated the complete asset management solution of critical valves from IMI CCI and placed an order for turnkey solution services that included service, repair, parts and upgrades on the entire fleet of 19 IMI CCI valves.