A customer in China planned to increase the steam temperature of the main steam and reheater steam line to 566 deg C (1050.8 deg F) and 596 deg C (1104.8 deg F) respectively to improve the plant efficiency. This required upgrading the existing IMI CCI high pressure (HP) and low pressure (LP) turbine bypass system including the turbine bypass valves, spraywater valves, and isolation valves. The customer sought a solution from multiple valve manufacturers.

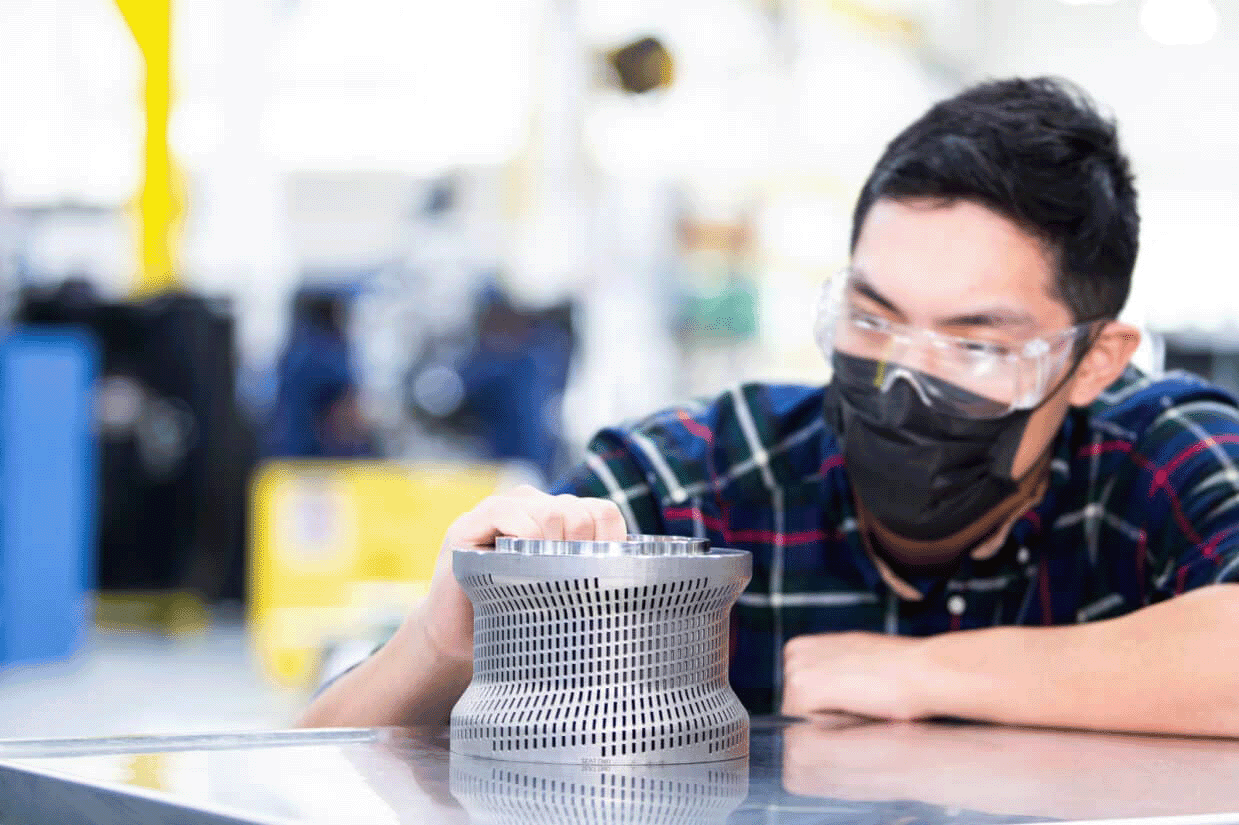

NBSE LP Bypass Valve

IMI CCI worked closely with both the end customer, as well as the design institute, to compare the current and future process conditions for the various operating scenarios and understand the impact of these conditions on the existing IMI CCI turbine bypass system installed. The IMI CCI team worked closely with the customer to engineer an optimised upgrade solution that would retain existing valve bodies and hydraulic actuation systems wherever possible to minimise changes to the existing piping system. Process condition analysis by our Valve Doctors® confirmed the ability to upgrade the trim design on three of the valves to meet new process conditions; retaining the existing valve body and actuator, resulting in cost savings to the end user. On the remaining three valves, complete valves had to be upgraded to meet the new process conditions. IMI CCI supplied the DRE series valve for the HP bypass system which can perform steam throttling with very high pressure drop combined with in-body desuperheating through spraywater injection. The valve is specifically designed for the cyclic operation of bypass systems and can operate to the wide variety of steam pressures and temperatures preferred by today’s most advanced thermal power plants. For the LP bypass system, IMI CCI supplied the NBSE series which has been specially designed for modern ultra-supercritical power plants load ramping and trip case requirements.

IMI CCI’s ability to engineer a customised solution, which provided value for the customer was rewarded with an order to supply the upgraded solution.