The terminal in the Caspian is one of the world’s largest oil and gas terminals. It receives and processes oil and gas from the Caspian Sea and exports gas and crude oil. IMI CCI had an installed base of 25 critical control valves at the site.

By the beginning of 2014 the terminal had reached its maximum capacity and started a project to increase the gas processing and export capacity. The impact of the project would be that three of the IMI CCI installed valves would require an increased flow capacity: the slug catcher gas-to-flare and two compressor gas-to-flare valves as well as a higher performance positioner.

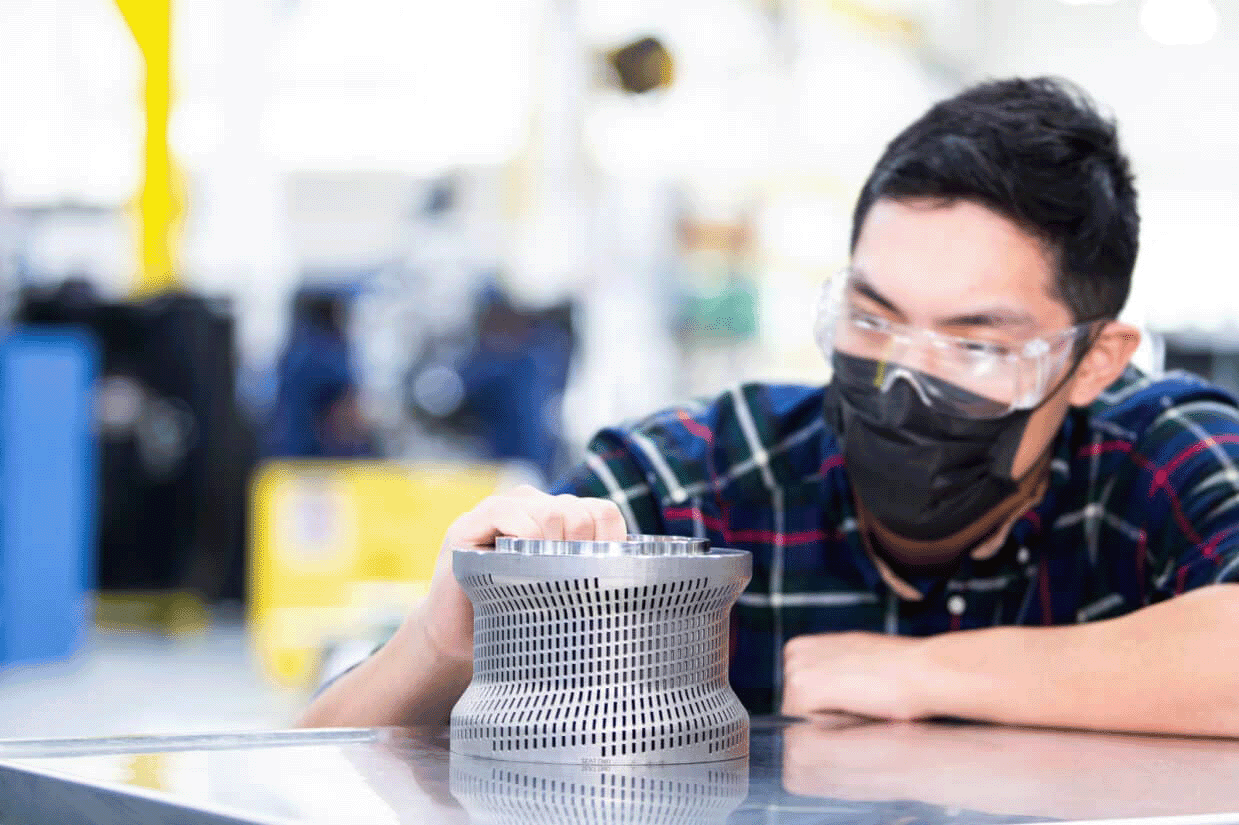

FasTrak smart positioner

The customer was happy with the previous performance of the valves and wanted to maintain the DRAG® technology on these applications. The IMI CCI team worked directly with the customer, analysing the process conditions and the installed schematics to provide a system solution to meet the demanding application requirements. The system solution recommended by the IMI CCI Valve Doctor® team eliminated the downstream eccentric expanders with a specially design DRAG® valve to match the customer’s piping. They also offered a FasTrak positioner which simplified the installation and start up time.

The solution resulted in a simplified installation with minimal impact to the existing piping. The valves were successfully delivered in time for installation during the annual summer shutdown.