Optimise performance and safety

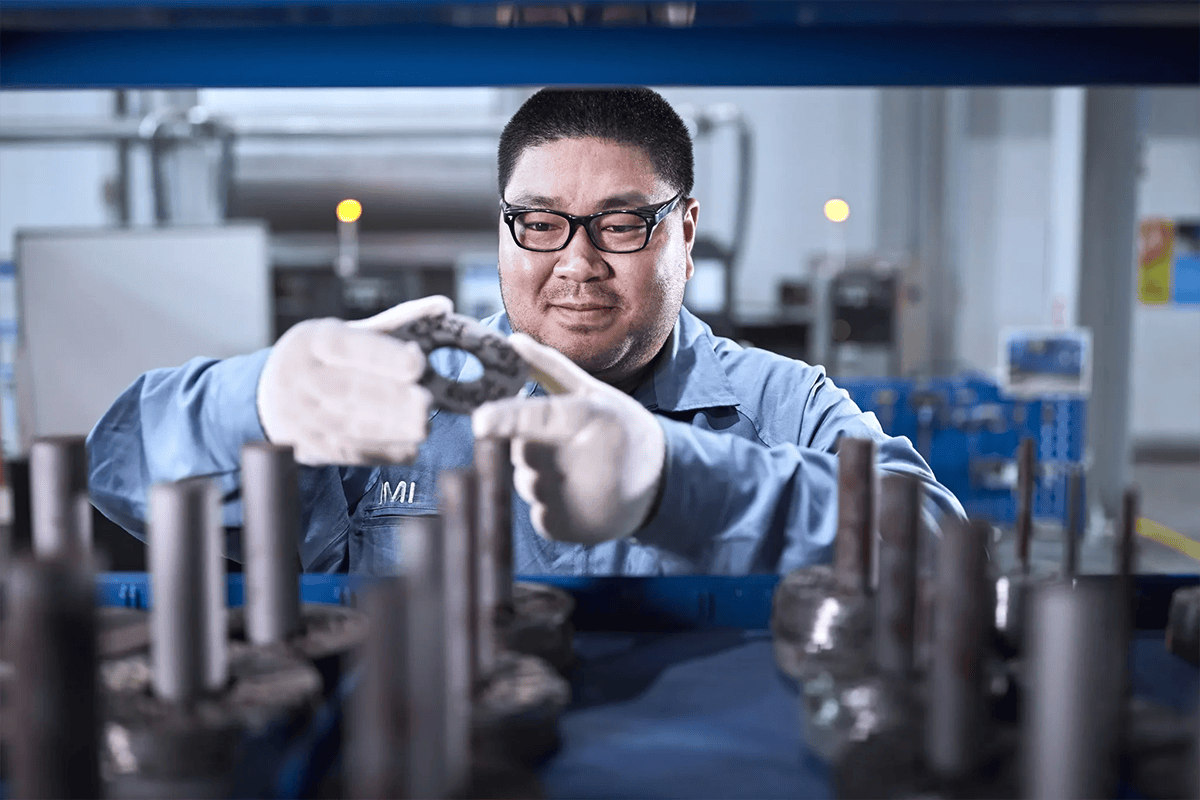

At IMI, we define world-class service support as a commitment to delivering exceptional experiences throughout every interaction. Our service support team is dedicated to providing unparalleled assistance, guidance, and resolution for you.

Our team is equipped with extensive product knowledge and expertise. We invest heavily in training and development to deliver a deep understanding of our solutions, their functionalities, and the industries they serve. This expertise allows us to offer comprehensive design and installation guidance, troubleshoot effectively, and provide valuable insights empowering you to leverage our solutions to their fullest potential.

Design and installation

Our team of Valve Doctors™ and Application Engineers draw on their extensive experience to tackle complex challenges. From design to installation, we ensure optimal performance and offer comprehensive asset management and maintenance solutions.

Service support

IMI offer comprehensive lifecycle maintenance programs, expert field services, service agreements, asset management, preventative maintenance, and support for planned outages. We prioritise maximising valve reliability and performance, ensuring smooth operation, minimising downtime, and providing peace of mind to customers.

Plant performance

A digital engineering service that uses data-driven analytics to identify and prevent problems in industrial systems. It improves plant safety, performance, and offers cost savings by avoiding unplanned shutdowns. Full system surveys and expert analysis optimise plant efficiency and reliability.

By combining these elements, we consistently deliver world-class service support that goes beyond resolving technical issues. We strive to create meaningful, long-term partnerships, helping you achieve your goals and maximise value.