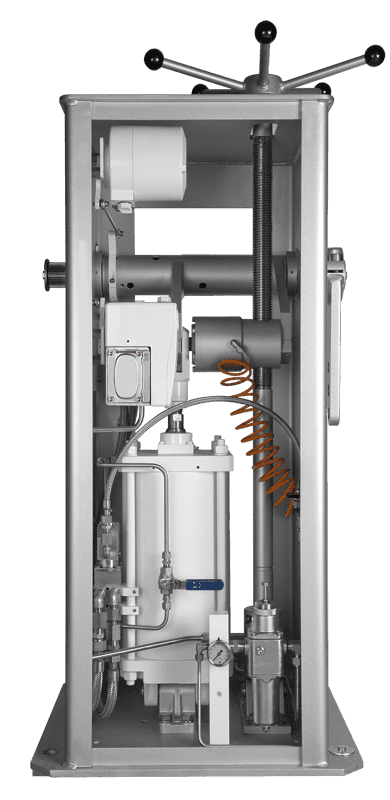

CMV Large Control Drive Enclosed Actuator

Control drive enclosed actuator with auto engaged manual override

The CMV series pneumatic actuator system consists of an actuator and a manual override integrated into a steel housing which is also a portable structure. This rugged construction guarantees continuous operation in harsh environments, for example in power stations, steel industries, petrochemical plants, desert areas, etc. This actuator is able to control final elements like dampers or hydraulic converters with high power actuators. In this actuator, the housing provides a double function of protection and a bearing frame. The engaging of the manual control is made automatically or manually through a dedicated switch.

- Actuator with manual override and lock.

- Portable within reinforced steel housing for sturdy support for high forces.

- Up to 4000 daNm.

- -20degC to 70degC.

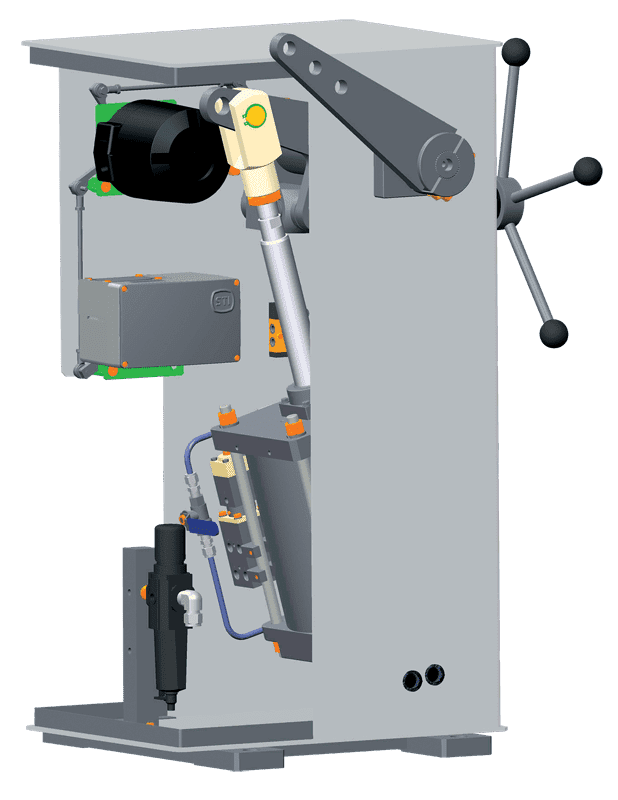

- Lever has 70deg operating angle for convenient orientation.

- Lever orientation variable on.

- Splined shaft.

- Typical operating pressure 7barg up to 10 bar.

- Mechanical position indicator.

- Large removal panels for ease of access and maintenance.

Product Specifications

Housing

- Carbon steel

Lever shaft

- Alloy steel 38 NiCrMo4 heat treated

Shaft support

- on bearing bronze for CMV-2 to CMV-4 spherical joints for CMV-1

External lever

- Carbon steel

Manual override

- Pneumatic by-pass function for manual override using an external lever

Bearing frame

- Carbon steel

Manual control screw

- Alloy steel 38 NiCrMo4 heat treated

Tubing & fittings

- Brass fittings and copper tubing (stainless steel 316 available on option)

Standard painting

- RAL 7030 grey

Lever features

- 70° operating angle

- Lever orientation variable on splined shaft

- Mechanical position indicator

Control signal

- 4 to 20 mA (3 to 15 psi)

Air supply

- Dry instrument air according to ISO 8573-1

Operating pressure

- Pneumatic version from 7 barg up to 10 barg (special version available on request)

Standard operating temperature

- -20°C to 70°C (lower or higher temperature on request)

Find your perfect flow control solution