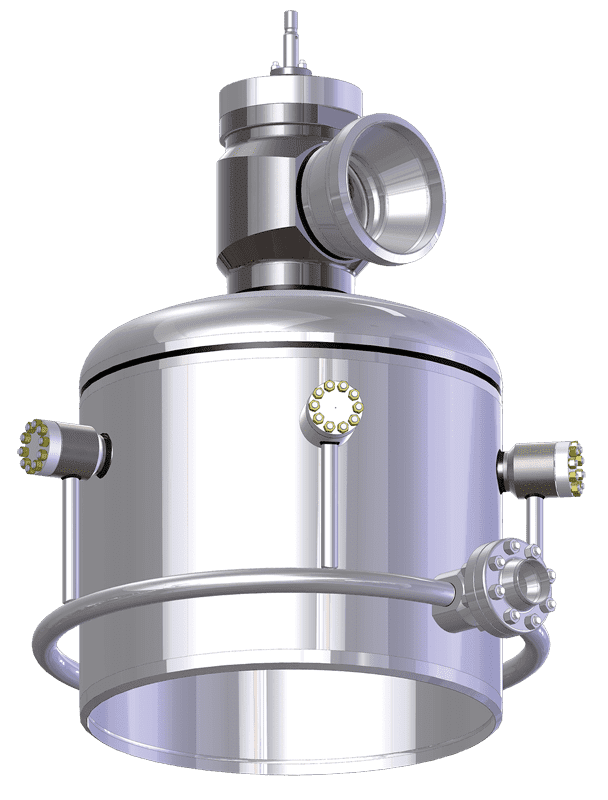

NBSE Low Pressure Turbine Bypass Valve

The NBSE is a steam conditioning valve used for steam throttling and desuperheating through spray water injection, directly at the outlet. Used for start-ups and load rejection, they dump steam from reheat lines to condenser until the steam temperature matches the turbine blade temperature.

With the range of available body materials, the NBSE valve can be used for steam pressures and temperatures of today’s most advanced single and double reheat thermal power plants.

- Specially designed for modern ultra supercritical power plants load ramping and trip case requirement.

- Forged body design with flow-to-close flow pattern.

- Available in pressure seal bonnet and bolted bonnet design.

- Can be equipped with hydraulic, electromechanical or pneumatic actuator.

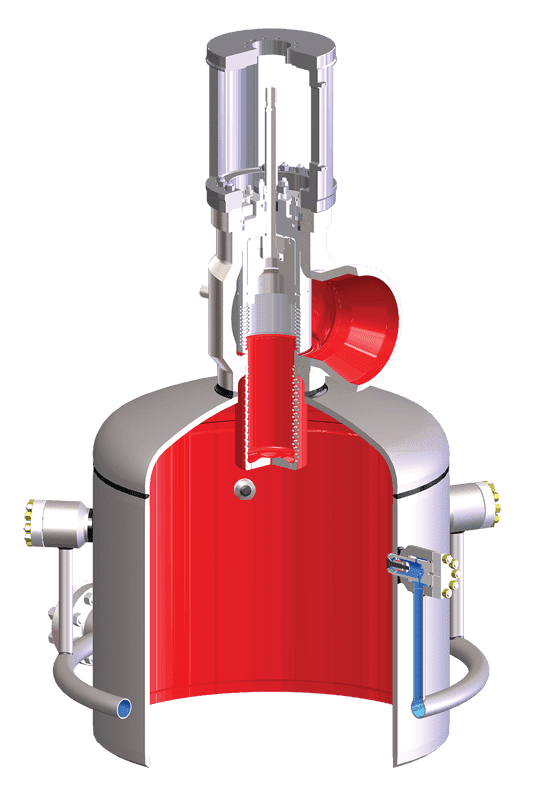

- Seal welded seat with Integral first stage PR tube allowing for quick maintenance and replaceable features.

- Spring loaded water injection nozzles.

- Different plug designs available.

Product Specifications

Body style

- Forged angle type valve body, flow direction – flow to close

Nozzle connection

- For steam pipes: butt-welding, acc. to customer?s requirement

- For spray water pipes: butt-welding, acc. to customer?s requirement

Trim design

- Welded seat ring, pilot operated trim

Steam data

- Temperature range: up to 630øC

- Inlet pressure: up to 80 bar

Seat leakage class

- EN 12266-1 Cl. B or MSS-SP61 or ANSI/ FCI 70.2 Cl. V

Actuation

- Hydraulic, electric or pneumatic actuator

Serviceability

- All internal trim parts, seat ring (welded), spray nozzles

Options

- Transition pieces for large pipe diameters and material compatibility

- Prewarming and/or drain connection available upon request

- Pressure seal and bolted bonnet design

Certification

- Certified acc. to PED 2014/68/EU

Design code

- EN 12516-2, others upon request

Find your perfect flow control solution