Goggle Valves

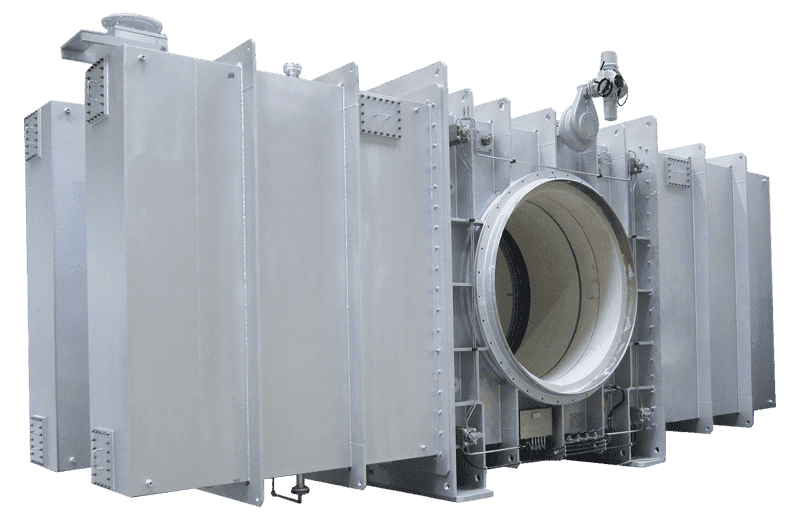

Open or enclosed design valves

IMI TH Jansen Goggle Valves are typically used for gaseous media, even with high dust content. Our valves comply with safety regulations for man-safe shut-off devices, which in a closed position must positively prevent the ingress of toxic gas into accessible ducts for maintenance or inspection purposes. Even in the event of a leakage the gas can either escape to the atmosphere (open design) or is collected in the hoods of the enclosure and can be safely extracted (enclosed design).

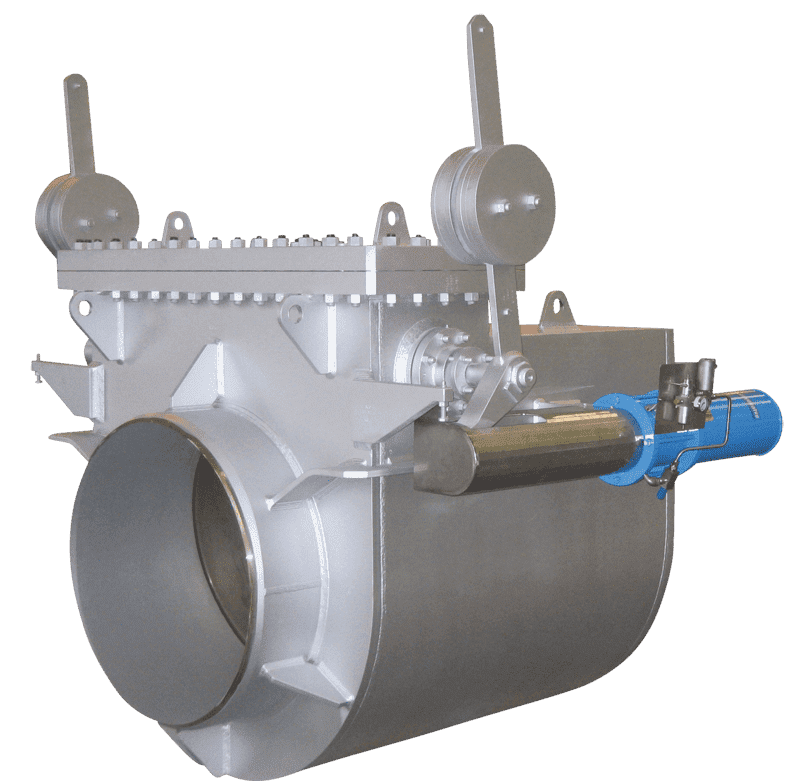

Sealing system- A clamping sleeve with an integrated expansion joint is bolted into the body and is moved in an axial direction to release the valve plate consisting of goggle and blind. After traversing, the valve plate is clamped between the sealing surfaces of the clamping sleeve and the opposite body surface and is sealed by elastic seals inserted into grooves on the sealing faces of goggle and blind-Different sealing materials are used according to the operating temperature and medium, from elastomeric seals (e.g. CR, FKM/FPM, VMQ) to encased fibre gaskets and sealing systems consisting of a soft sealing material with an additional metallic seal (Morton edge).

Actuation- On all IMI TH Jansen Goggle Valves, the actuation sequence of clamping and unclamping the valve plate is achieved by two independent actuating systems: one system for the clamping sleeve and a separate system for traversing the valve plate.- Hand and chain wheels, electric or hydraulic systems available.- Electric control cabinets for automatic operation as well as hydraulic units are available.

- Comply with the appropriate safety regulations.

- Open or enclosed design.

- Three different duct installation positions have been developed.

Find your perfect flow control solution