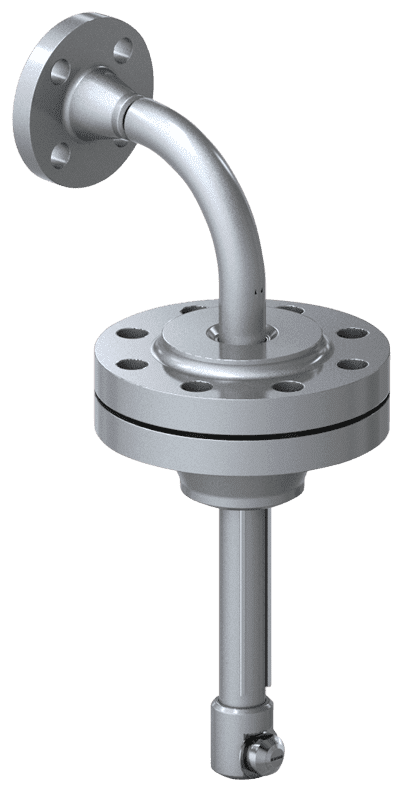

DA4S Steam Desuperheater

Steam desuperheater with mechanical water atomisation and integrated spraywater control

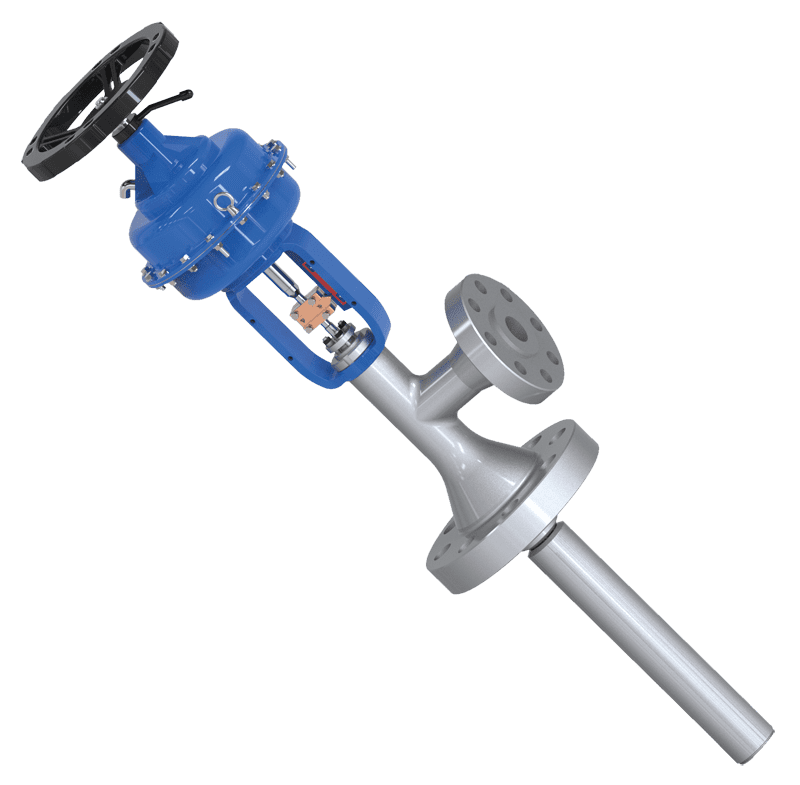

The BTG Steam Desuperheater DA4S is a combination of an injection nozzle and a control valve. It is inserted in a steam line of minimum diameter DN 150 mm/6″. The nozzle is inserted in the steam pipe through a flanged pipe stud that is welded to the steam pipe.

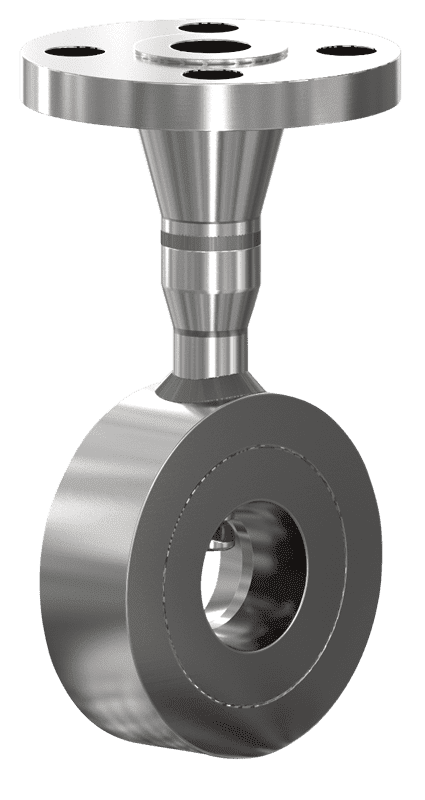

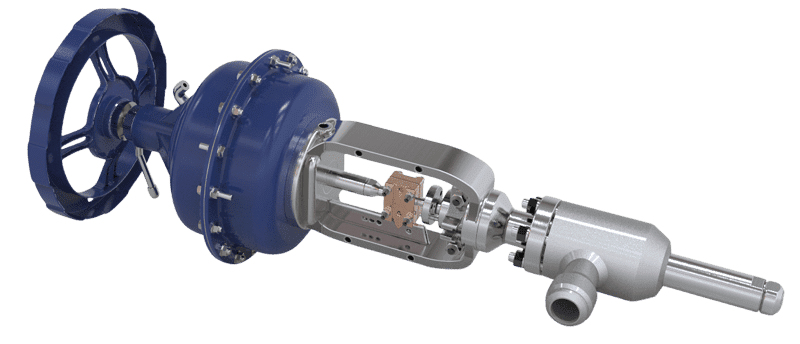

The cooling water from the water pipe enters the area between the front part of the inlet pipe and the injection nozzle. The control plug is guided in the injection nozzle. The injection nozzle and the sealing surfaces of the control plug are lapped together to ensure tight shut-off. When the plug is in the closed position all water admission holes in the injection cage will also be closed. As the plug lifts from the injection nozzle seat, it simultaneously opens up a number of water admission holes in the injection cage. The number of free ports will therefore be directly related to the lift of the plug. The inlet or admission holes in the injection cage are arranged so that a, from the control point of view, good characteristic is obtained. The cooling water, that enters the injection cage through the tangentially positioned admission holes, is induced to a fast rotation around the tip of the plug and is subsequently ejected through the nozzle as a rapidly evaporating cone shaped mist. The quantity of injected cooling water depends on the number and size of the ports that are opened up by the control plug. The signal from the temperature transmitter located downstream of the desuperheater controls the position of the plug via the actuator.

Product Specifications

Capacity

- 7 different injection nozzle sizes: A, B, C, D, E, EO and F with following max. Kv/Cv values: A = 0.22/0.25, B = 0.6/0.69, C = 1.6/1.8, D = 3.0/3.4, E = 4.7/5.4, EO = 6.4/7.4, F = 9.7/11.2

Control characteristic (Integrated control valve)

- Almost equal percentage (logarithmic)

Control range (Water)

- 40:1

Pressure class

- DIN PN 16 – 400

- ANSI 150 – 2500

Max steam temperature

- 550ºC (1022ºF)

Materials

- Housing: Low alloy steel CS17CrMo55, ~ equiv. to ASTM A217WC6

- Plug: Stainless steel X20Cr13, ~ equiv. to AISI 420, surface hardened

- Atomiser: Stainless steel X20Cr13, ~ equiv. to AISI 420, surface hardened

- Nozzle head: Steel X90 CrMoV 18, ~equiv. to ASTM 440B.

- Stuffing box packing: Graphite

Other options

- The DA4S is a standardized product, with options limited to what is described within this document. If customized adaptations (e.g. but not limited to accessories, painting, materials, etc.) are desired, IMI CCI recommends the DA4.

- Note that any price quoted for the DA4S assumes strict adherence to the specifications described within this document.

Find your perfect flow control solution