Control Valves for General Applications with Customisable Trim

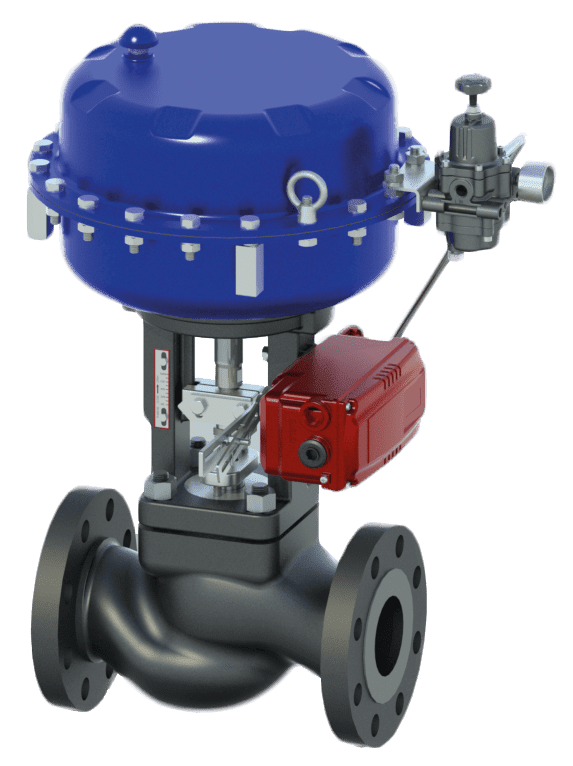

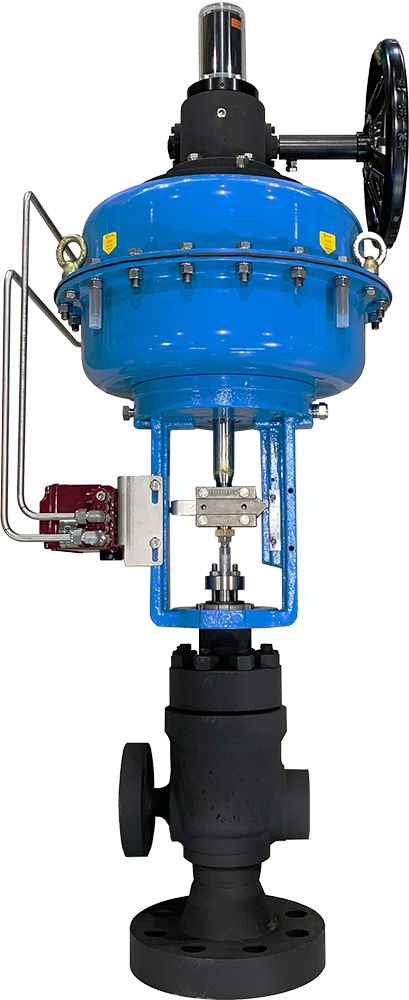

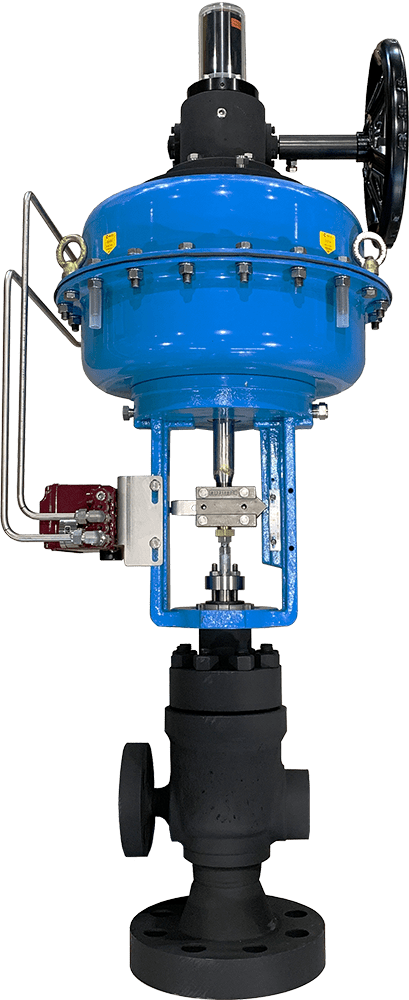

Globe and angle control valves for general applications

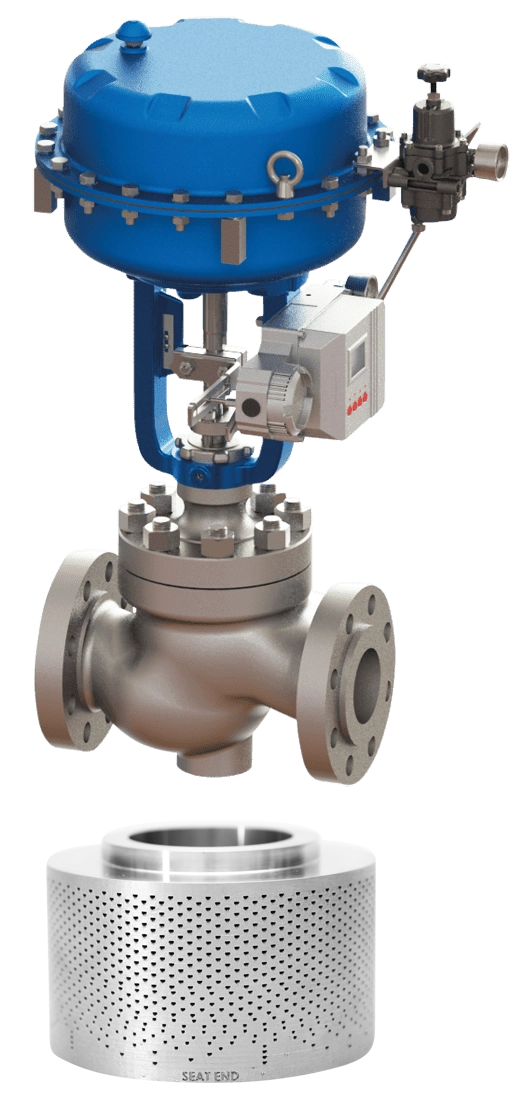

840-3D globe and 860-3D angle control valves are manufactured using the most advanced techniques that benefit from highly customised 3D printed trim. Designed for use in a wide range of applications in the oil and gas, power and nuclear sectors, the 840-3D and 860-3D offer limitless opportunities. Featuring fit-for-purpose trim, the valves are produced with custom multi-path and multi-stage channels that allow compact trim design with a high number of stages that reduce exit velocity. This greatly improves the reliability of the valve interior, reducing potential damage at start-up and during throttling at low stroke.

Bringing multi-path, multi-stage, low noise and anti-cavitation DRAG® technology to an entirely new level, the 840/860-3D valves provide excellent control and first-class rangeability. Whatever the application, they comfortably deliver great process control while also minimising any losses that could be caused by valve leakage.

- Simple to change capacity and flexible trim design.

- Process conditions may change over time. With the use of additive manufacturing and its compact design characteristics, new valve internals can be redesigned or modified to suit your new process conditions.

- Tight shutoff.

- Shut-off classes from ANSI IV through VI are available.

- Easy maintenance.

- Top entry design allows rapid inspection or trim change.

- Actuation.

- A wide selection of actuation is available including pneumatic, electric and top-mounted manual options.

Product Specifications

Valve size

- 1” through 16”

Ratings

- 150# – 2500# ASME B16.34 standard pressure rating*

End connections

- Flanged ends (FF, RF, RTJ) Weld ends (BW, SW)

Flow characterisation

- Linear, modified equal percentage or equal percentage

Seat leakage

- ANSI/FCI 70.2 Leakage class IV, V, VI

Temperature range

- -60 ~ 580°C

Noise level

- Typically, ˂85 dBA

Safety

- Fail-to-close on the loss of air

- Fail-to-open on the loss of air

Find your perfect flow control solution