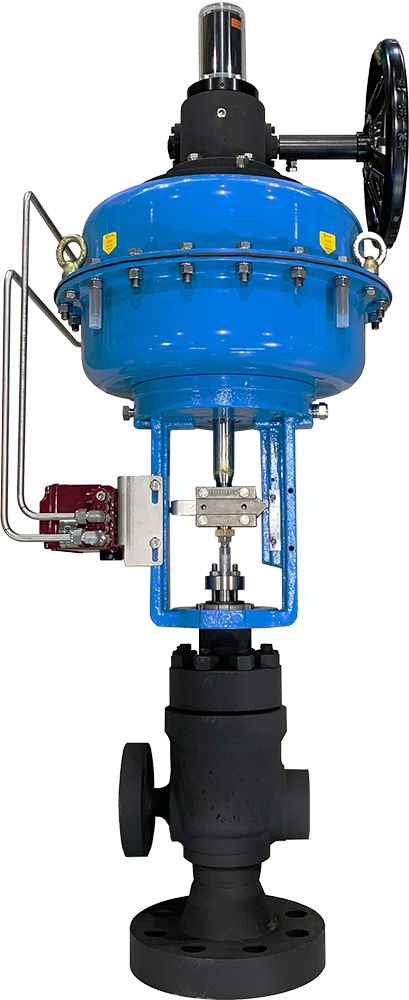

840GC Control Valves for General Service Applications

The pre-configured 840GC control valve offers enhanced features to handle the most demanding general service applications. The proven technology of the flare hole design and the cascade anti-cavitation trim have the ability to manage high flashing water applications and drastically reduce damage as a result of cavitation.

The 840GC design was also upgraded with the latest technology and materials allowing the design to be further optimised with fewer parts, quick change trim for easy maintenance, better load distribution and improved performance within the standard product range.

In severe climate conditions, the 840GC control valve can be equipped with the optional MSD-III diaphragm actuator designed to perform even at extreme temperatures of -55ºC.

The 840GC is optimised with a reduced number of components, commonality of parts and increased flexibility within the standard product range.

- Quick change trim- – No screwed or welded trim components.

- Proven trim design – Ported cage, drilled-hole cage, flare-hole cage and cascade anti-cavitation.

- Multi-spring diaphragm actuator- – Multi-spring design improves hysteresis and dead band performance.

- Accessories- – A full range of accessories are available to meet requirements.

Product Specifications

Body type

- Globe

Valve size

- 1”, 1-1/2”, 2”, 3”, 4”, 6″, 8”

Ratings

- ASME 150, 300 and 600

End connections

- Weld ends per ASME B16.25 & 11

- Flanged raised face per ASME B16.5

Flow characterisation

- Equal percentage & linear

Seat leakage

- Standard ANSI class IV, Optional ANSI class V or VI

Seat type

- Gasket

Actuator type

- Pneumatic, electric

Pneumatic actuator

- MSD-III diaphragm

Temperature range (general)

- -46 ~ 565 °C for unbalanced trim

- -46 ~ 315 °C for balanced trim

Find your perfect flow control solution