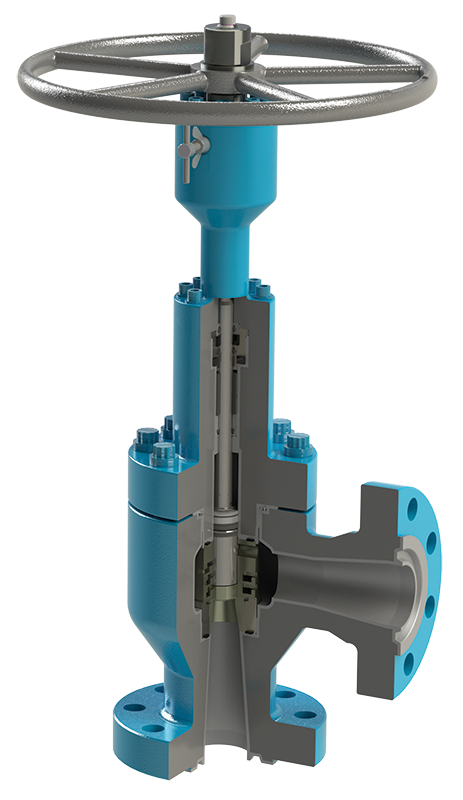

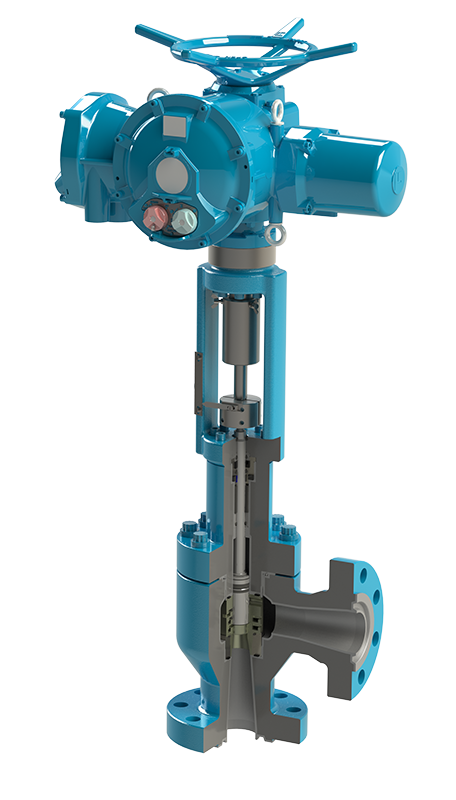

100DPC Multi-trim DRAG® Production Choke Valve

Located at the wellhead, where the well-fluid is first extracted from the field, the production choke valve is arguably the most severe service application in the oil and gas industry. It is essential for providing controlled pressure for downstream processes and needs to handle some of the most difficult fluids and conditions in the entire oil and gas process chain.

With the 100DPC production choke valve, IMI CCI have standardised a product range to maximise valve service life and minimse total valve life cycle costs by addressing the specific severe service concerns which apply to this arduous application.

- Multi-phase fluid which can make accurate sizing difficult.

- High pressure drop which leads to high kinetic energy levels, which causes erosion, vibration and noise.

- Potential for high solid content which leads to further erosion issues and potentially clogging

- High concentrations of acids (H2S, CO2), chlorides and chemicals which can cause corrosion issues

- Long field life with large variation of inlet pressures which subsequently require a wide range of CV’s to maintain flow rates

- The 100DPC production choke valve, addresses the application-specific concerns above by incorporating the following aspects into the product design:

- Erosion, vibration and noise are symptoms of high kinetic energy levels. Guarantees optimum wear resistance in erosive conditions due to energy & velocity control with multi-stage & multi path DRAG® trim technology.

- Key trim components are produced from solid tungsten carbide for additional erosion resistance.

- To address corrosion, all wetted surfaces on pressure boundary parts are weld overlayed with Inconel 625. In addition, all internal wetted metallic parts are made out of Inconel 718 as standard. No elastomeric seals used apart from the stem packing.

- Large, expanding flow passages are used to allow the valve to handle solids and dirty fluids while minimising the potential for clogging.

- Characterised trim possible to maximise CV range. Also, trims are available in single and multi-stage configuration. Interchangeability of parts guaranteed.

- The design of internals and packing arrangements are optimised for easy maintenance and no components are screwed or welded to the pressure boundary parts.

Product Specifications

Materials

- Body / bonnet: AISI 4130 60K/ASTM A182 F22 60K with 3.0 mm inconel 625 weld overlay

- Trim: 718 nickel alloy with solid tungsten carbide

Material Classes

- API material class HH as standard. Other classes available on request

Pressure Drop

- Up to 600 bar pressure drop

Pressure rating and sizes

- ANSI 1500 – 2500: 1-1/2”, 2”, 3”, 4”, 5”, 6” 8”, 10”

- API 5000 – 10000: 1-13/16”, 2-1/16”, 2-9/16, 3-1/8”, 3-1/16”, 4-1/16”, 5-1/8”, 7-1/16”, 9”

Temperature rating

- Design temperature: -46°C to 150°C

Quality level

- Standard: ASME B16.34; API PSL2; API PSL3 & API PSL3(G); NACE MR0175

- Optional: PSL4 on request

Shut-off class

- Standard: ANSI/FCI Class IV & Class V

Actuator types

- Standard: Manual handwheel & electric motor operated

- Optional: Pneumatic; hydraulic

Find your perfect flow control solution