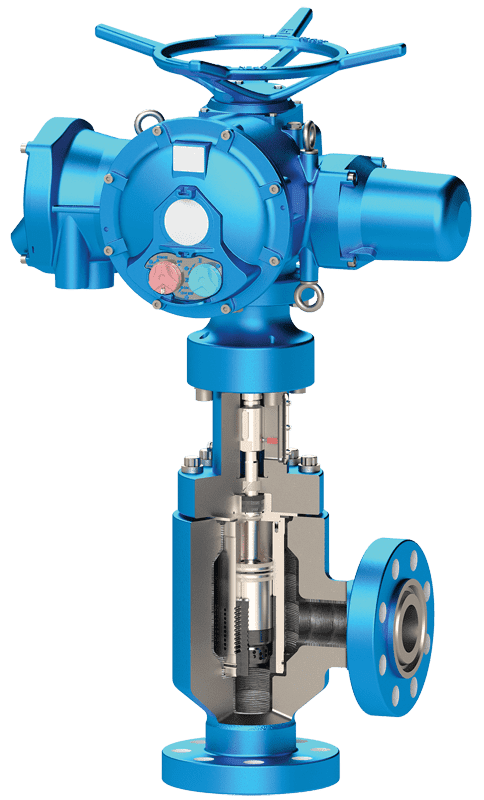

100DWI Water Injection Choke

Water injection choke for enhanced oil recovery

Water-flooding or water injection is applied to increase pressure and thereby stimulate production in oil fields. The water injection valve is located at the injection site and is responsible for controlling the injection flow and pressure. The primary value of the 100DWI is the greatly increased valve service life thanks to our enhanced cavitation and erosion control mechanisms.

Our two technology options are:

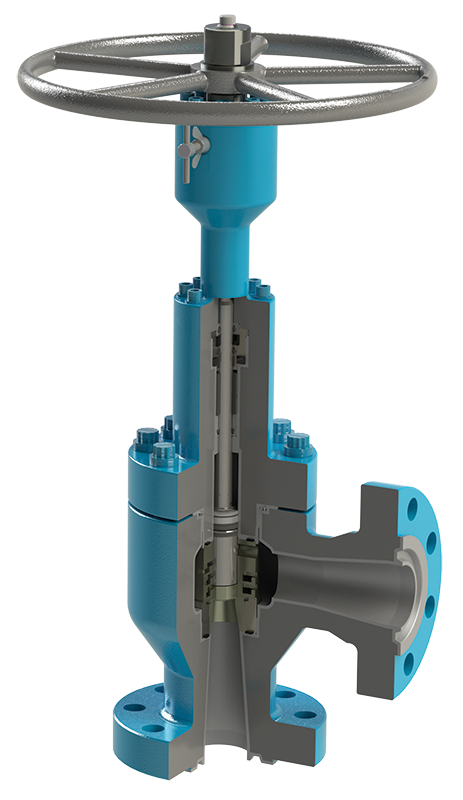

- Advanced cavitation control application – A cost effective single or multi stage cage trim (metal, tungsten carbide or Stellite™ + metal), anti-cavitation choke valve range. This solution is predominantly for clean water applications and for low pressure differentials in general (~200-250 bar).

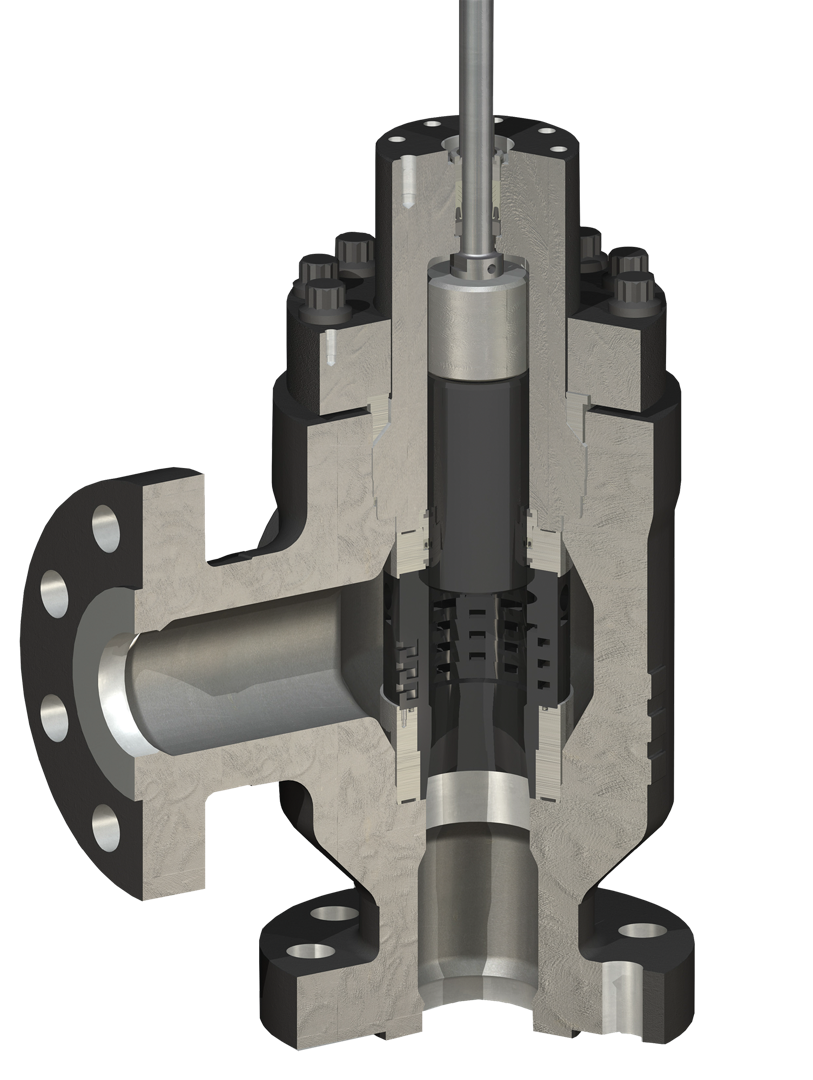

- Multi-stage/multi-path anti-cav solution – Our well known and field proven premium trim design, ensures velocity and erosion control in a tungsten carbide trim. The technology is further optimised for cavitation service, designed for dirty water and/or high severity applications.

Product Specifications

Connections (larger sizes on request)

- 1.5” to 6”

Design temperature

- -29°C to 121°C

Shut-off class

- Up to class V

Quality

- 3.1 material cert standard

- 3.2 material cert optional

Noise prediction

- ISA S75.17; IEC 534-8-3

Design codes

- API 6A

- ISO 10423

- ASME B16.34

Certifications

- PR2, NACE, fugitive emission optional, fire safe by design

Optional special testing

- Capacity, fugitive emissions

Pressure ratings

- Up to ASME 1500 or API 5000

Find your perfect flow control solution