Startups are frequently seen as disrupters of the status quo, while more well-established organisations appear better at optimising their own products and services. IMI’s Growth Hub process has not only very successfully challenged such well-established assumptions but also proven to be highly dynamic and innovative in delivering value to its customers.

Originally developed from a growth accelerator process first tested by IMI in 2018, Growth Hub has since evolved into a series of sprint cycles and stage-gated processes focused on finding solutions to real industry problems. Not only has it developed genuine, cutting-edge solutions, but it has in the process, generated millions of pounds of new business as it has done so.

Despite its success, however, Growth Hub is still relatively new to many potential stakeholders. This article explains how Growth Hub works and offers examples of how it has very successfully solved problems in power generation – one of the industries set to benefit most from the ground-breaking work taking place across IMI.

The Growth Hub process can be divided into four distinct phases of activity, with the focus throughout being on customer feedback and how best to develop effective solutions quickly.

So, how has it worked in practice? Let’s look at how Growth Hub has delivered value in one of IMI’s core markets: the power generation industry.

Good ideas are key to achieving better results in today’s power generation plants. Optimising performance, improving the reliability and availability of plant assets and minimising maintenance times are goals that will be familiar to most site managers. Having said that, IMI’s Growth Hub is not just focused on these short-term changes, as valuable as they can be. Instead, it also focuses on laying the groundwork for longer-term goals, such as automation, digitisation and, perhaps most important of all, decarbonisation.

Take hydrogen fuel, for example. The use of hydrogen as a source of fuel was a key part of the 2015 Paris Agreement, yet progress on green production has been slow. Part of this is down to a lack of access to the right technology, especially so in those more remote geographical areas where there is an abundance of renewable energy resources.

Hydrogen will prove central to decarbonisation and the energy transition and is set to grow from 2% to 18% of the energy mix by 2050. With IMI expanding its portfolio and solutions throughout the hydrogen value chain, the Growth Hub team developed a low-risk solution for decarbonising their on-site operations. The result was the IMI VIVO Electrolyser which converts water into hydrogen using renewable electricity and creates ‘green’ hydrogen. Marketed as a packaged ‘turnkey’ solution, the electrolyser is a complete, packaged solution that includes the electrolyser itself, as well as control and storage.

The technology will play a central role in decarbonising manufacturing sectors that cannot be electrified, this being the rationale that underpins this particular Growth Hub innovation. Basically, it permits a much wider adoption of sustainable energy-generating technology, and the electrolyser’s turnkey configuration makes it adaptable to customer specifications. It is already scheduled to be used across two UK research facilities supporting IMI’s research into green technology and eco fuels.

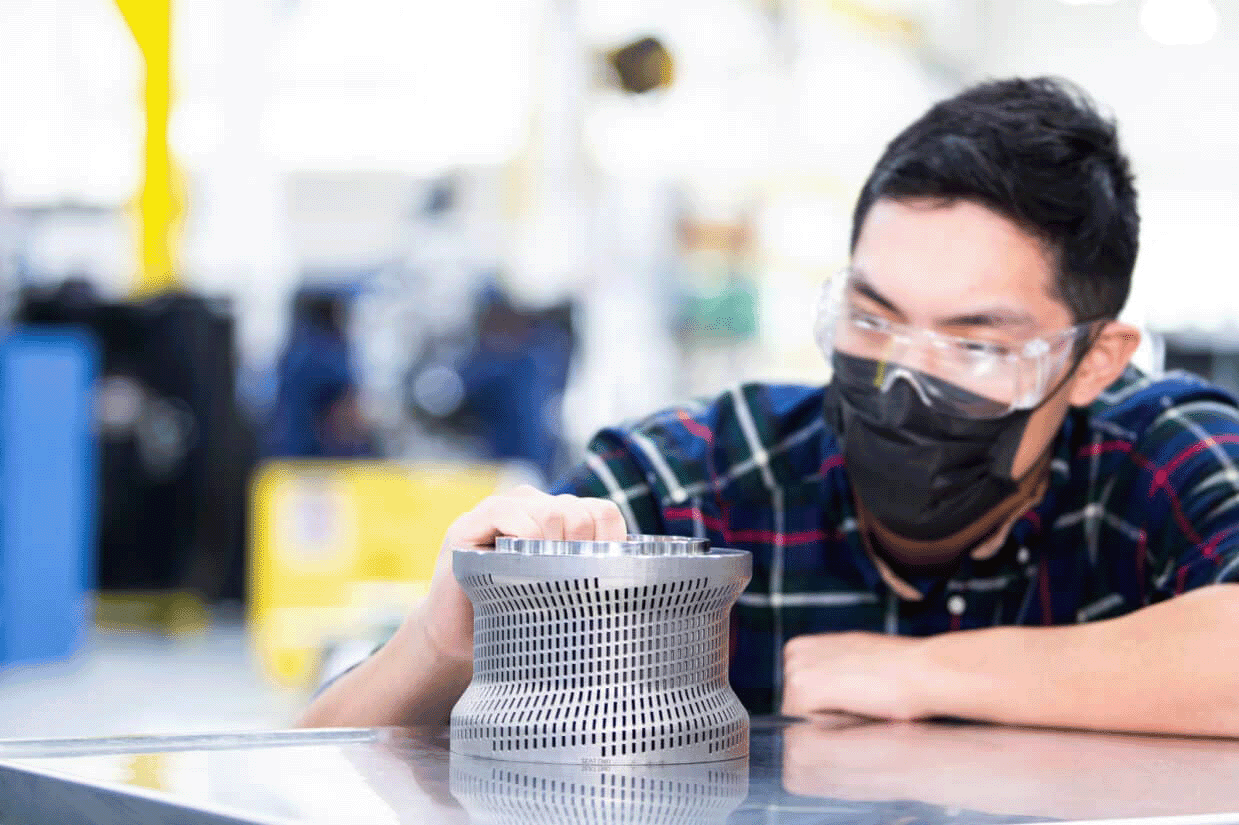

With demands on today’s energy-generating companies rising exponentially, plants are cycling more frequently, and parts are subsequently placed under considerable stress. Control valves are particularly likely to degrade and fail prematurely, which impacts not only process control optimisation but plant performance and reliability as a whole. Of course, replacing failing valves is rarely fast, cost-effective or practical, which led Growth Hub to develop another successful innovation, its Retrofit3D valve trim replacement solution.

Once dedicated teams collect all the trim-related details needed to replace existing valve trim the manufacturing and installation process moves quickly. Manufactured with cutting-edge additive as well as traditional manufacturing methods, the Retrofit3D trim is engineered to a power plant’s operating environment and with a shorter lead time and lower cost than with traditional maintenance methods. Installation takes hours rather than days and can be undertaken during scheduled maintenance periods.

The solution is proving successful in the power generation industry, where retrofitting is significantly more cost-effective than complete valve replacement which is a significant, capital expense project. The fact that the process is fast has led to far less plant downtime while also delivering greater process control,. As one power plant manager in North America put it:

‘It is expensive and time-consuming to replace a valve since it requires a non-destructive evaluation (NDE), change management and multiple approvals. Being able to simply drop in a trim set – that is huge. We just had to change the part numbers in the inventory system, and we were done. It was a far less expensive and much easier solution.’

Solving the problems that keep businesses up at night is far from straightforward, and IMI recognises that it cannot always be done with in-house talent alone. That’s why Growth Hub actively encourages engagement from further afield. This engagement could be with thought leaders from the power generation sector, subject matter experts and academics, new and existing customer project teams, or even startups looking to leverage the knowledge, reach and influence of a global business.

Growth Hub is there to untangle some of the power generation industry’s thorniest problems. But it’s also about the time, resources and dedication necessary to take a problem-solving idea to the next level. This represents a huge opportunity for the stakeholders mentioned above.

Some might see the Growth Hub as another way of carrying out project management for startups. But the initiative is far more involved than this and positions creative thinkers alongside technical experts to deliver real market innovation. It incubates the very best ideas and pushes at the envelope of what’s possible from engineering today. In this sense, it cuts to the heart of what IMI does as a business.