Company News

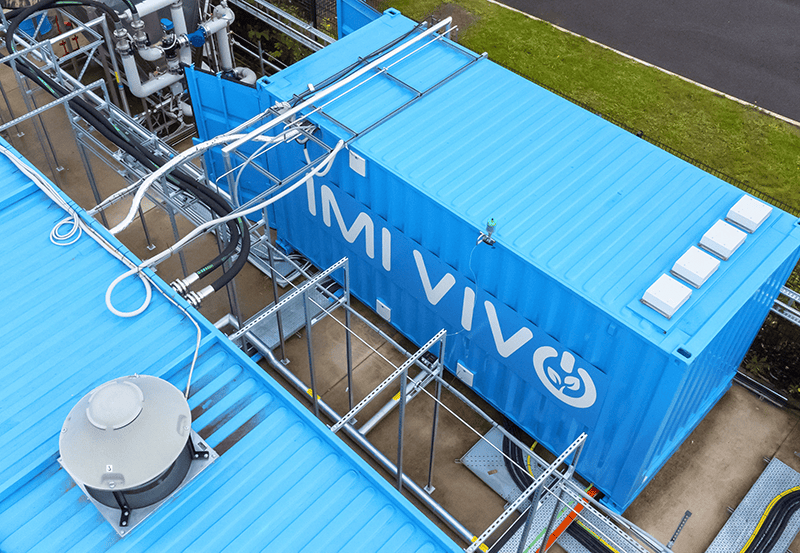

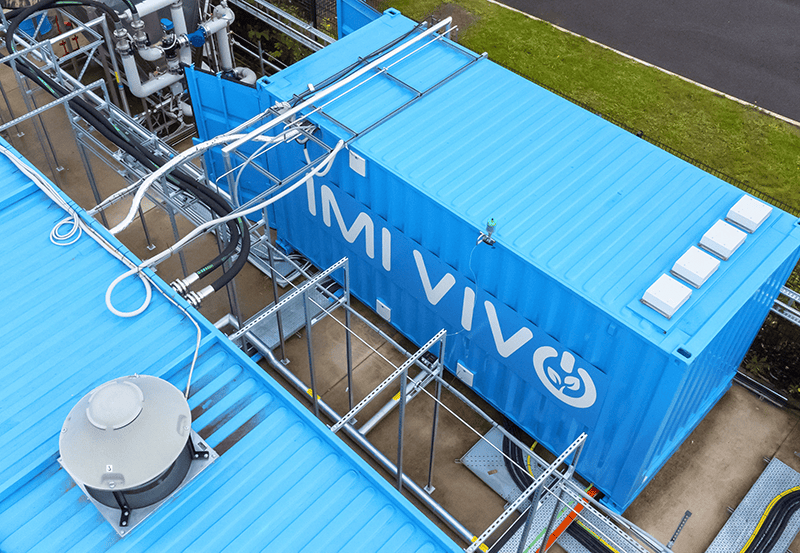

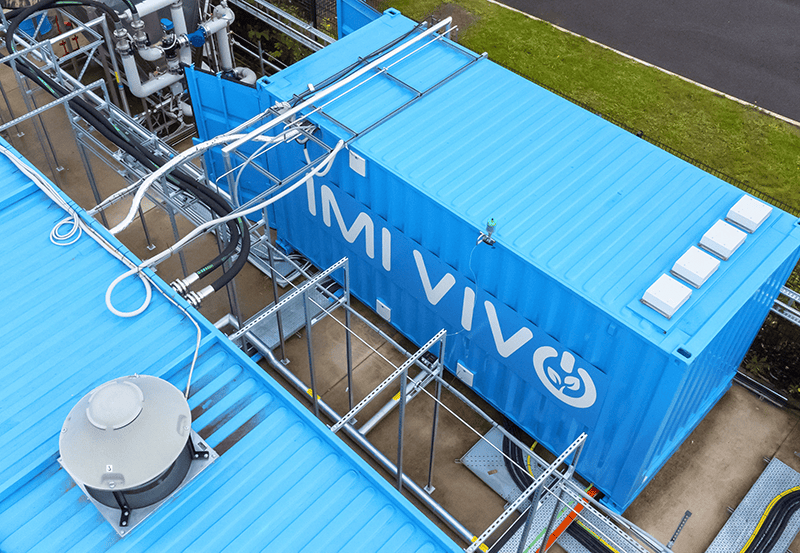

IMI delivers £15m of orders for hydrogen value chain in 2023

In 2023, IMI achieved a record year for orders in the hydrogen value chain, doubling its 2022 orders to deliver £15 million worth of projects supporting hydrogen generation.

Tags

In 2023, IMI achieved a record year for orders in the hydrogen value chain, doubling its 2022 orders to deliver £15 million worth of projects supporting hydrogen generation.

The EroSolve Metamorphic Trim solved clogging valve issues for major oil & gas producer on an offshore platform, significantly reducing OPEX.

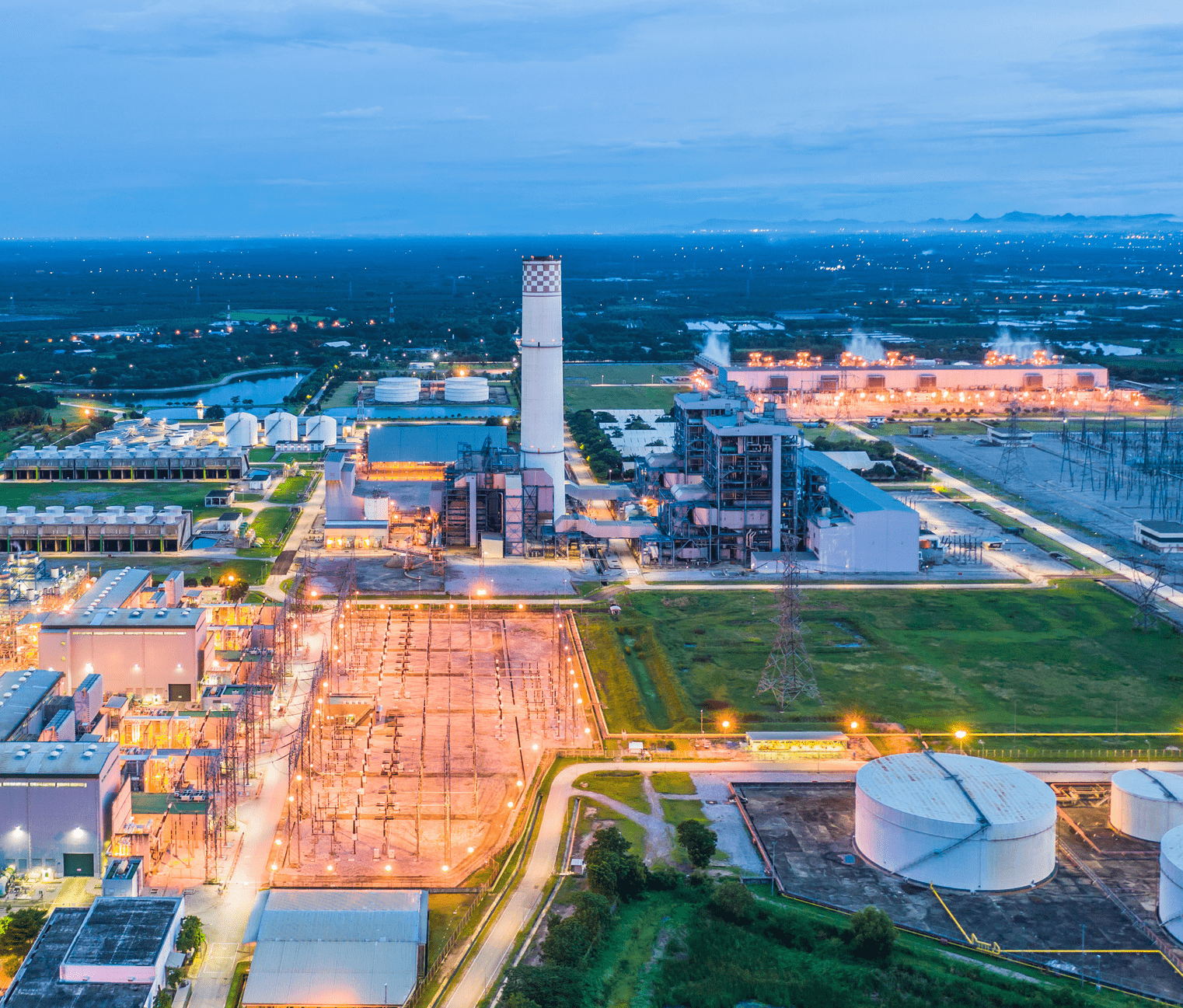

South Korean CCPP solve erosion and flashing issue in blowdown valves with EroSolve Flashing solution, reducing costs and improving safety.

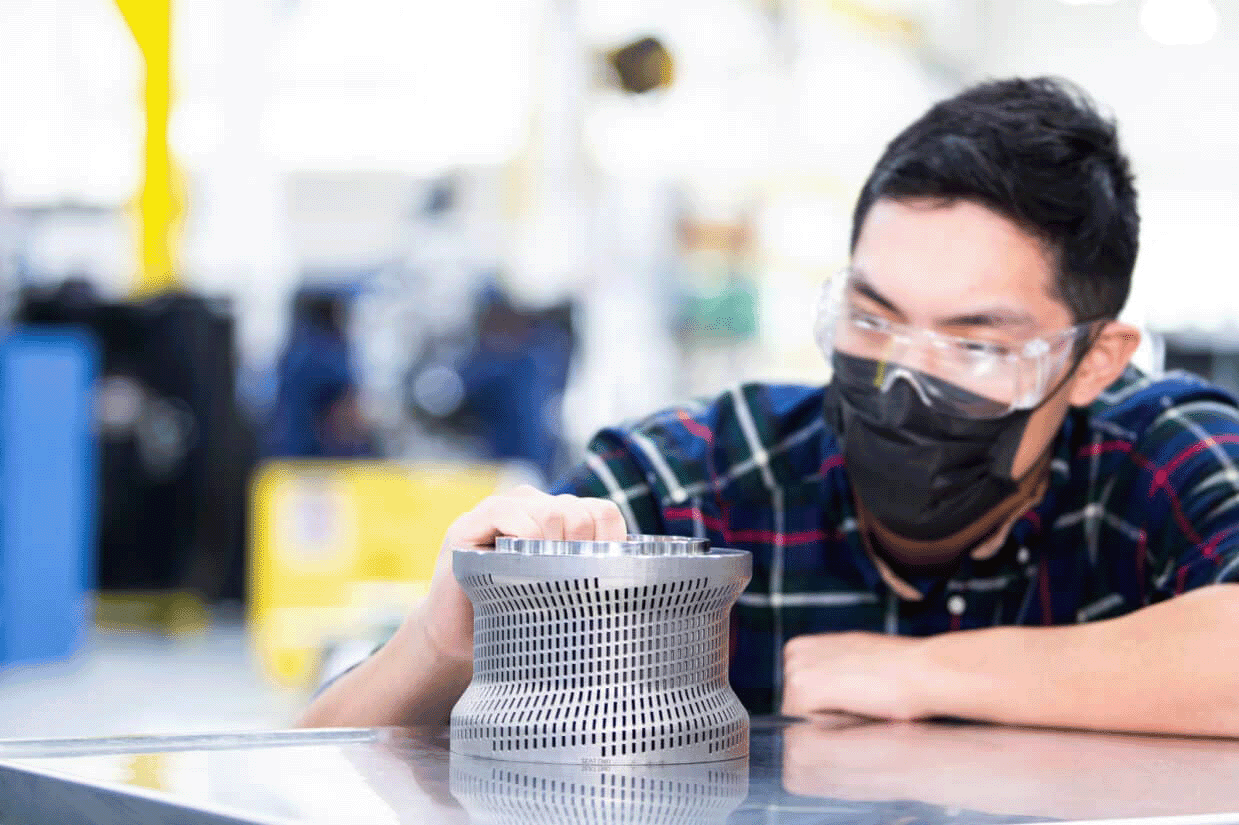

Find out why our Valve Doctors™ are the key to breakthrough engineering for a better world and how they support our customers with complex engineering challenges

How DRAG® technology reshaped the industry through multi-stage pressure drop, addressing cavitation, erosion, noise and vibration issues.

IMI Critical expands its portfolio with electrolyser technology that generates green hydrogen from renewable energy sources.

39 results