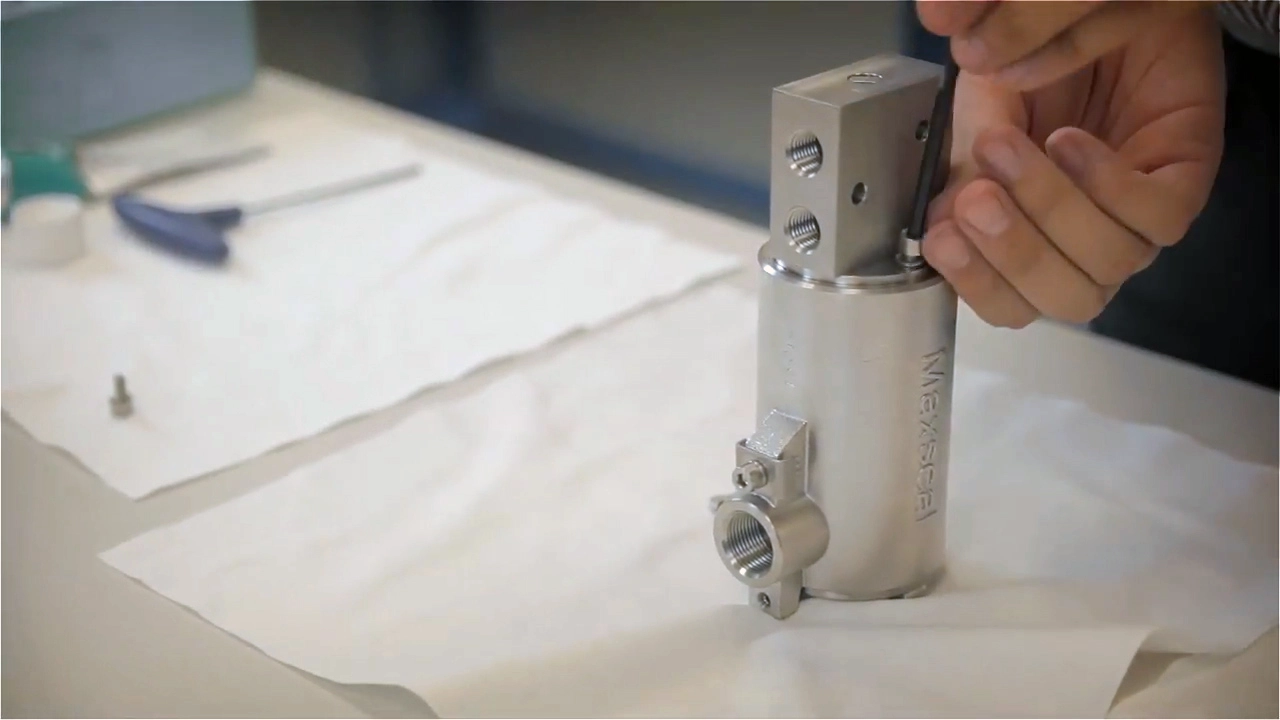

Key Technologies

Maxseal smart solenoid valves

Our Maxseal Solenoid Valve portfolio provides you with world leading safety for control of both pneumatic and hydraulic-operated equipment. The valves range from ¼” to 6” (6.35 mm to 152.4 mm) with a large built-in safety margin and a force friction ratio of >10.