As IMI’s critical flow control specialists, we possess extensive experience and expertise spanning decades in flow control solutions utilising valves, actuators, and other technologies to tackle complex challenges across industries.

Market leading solutions

Specialised flow control solutions for vital industries including oil and gas, power generation, petrochemical, marine, pharmaceutical, and other heavy industry. Our broad portfolio of industrial valves, including control valves, safety valves, and isolation valves, along with actuators and other products, allows us to offer customised solutions to meet the critical demands of these key sectors.

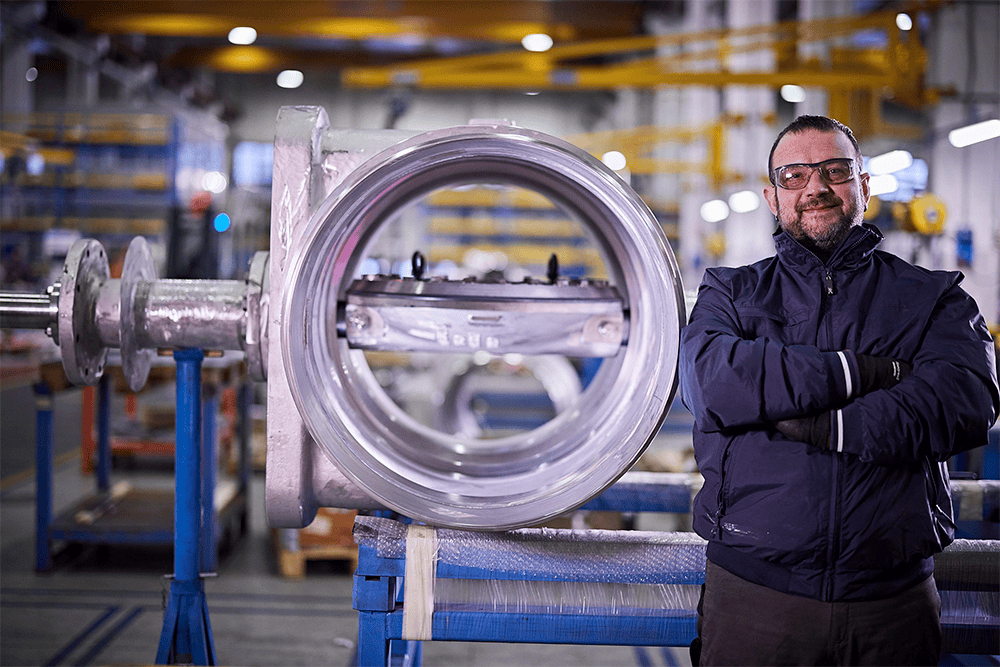

With expertise in developing industrial valves and instrumentation for extreme conditions, IMI delivers reliable and effective flow control to enable efficient and safe operations in the most challenging industrial environments.

World class valves and actuators

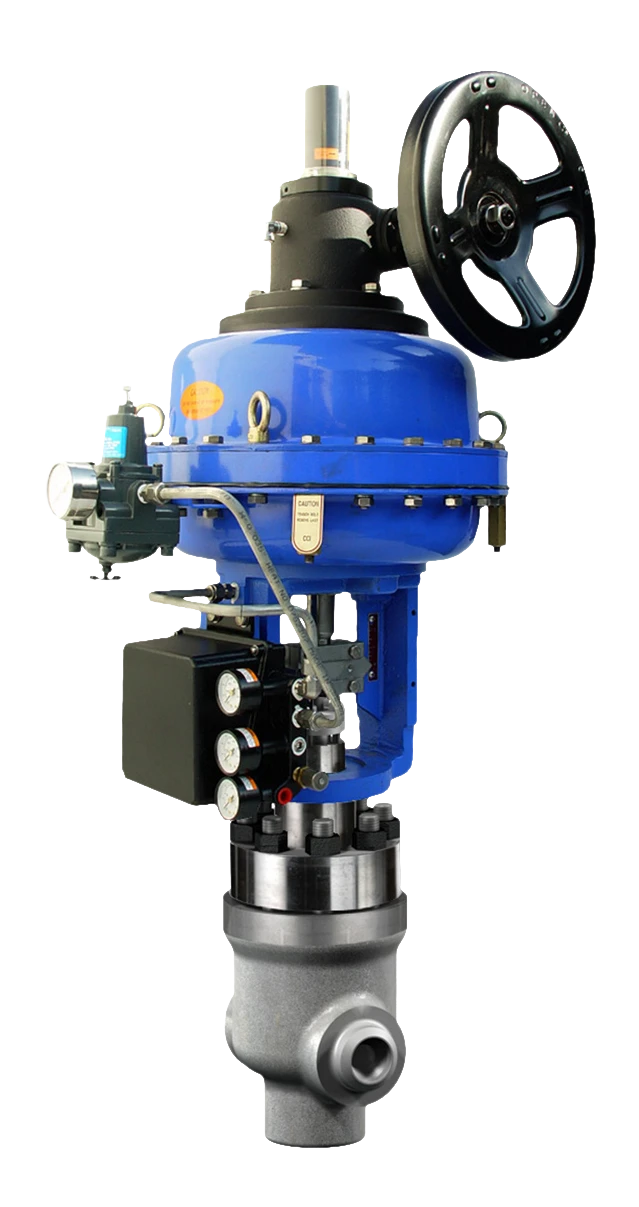

Control valves

Our control valve portfolio covers general, semi-severe, and severe service applications. Advanced technologies enable you to achieve the perfect balance between ease of installation, noise reduction, precise control, and maximum reliability.

- Attemperators and desuperheaters

- Boiler level control

- Bypass valves

- Choke valves

- Globe valves

- HIPPS

- Turbine bypass valves

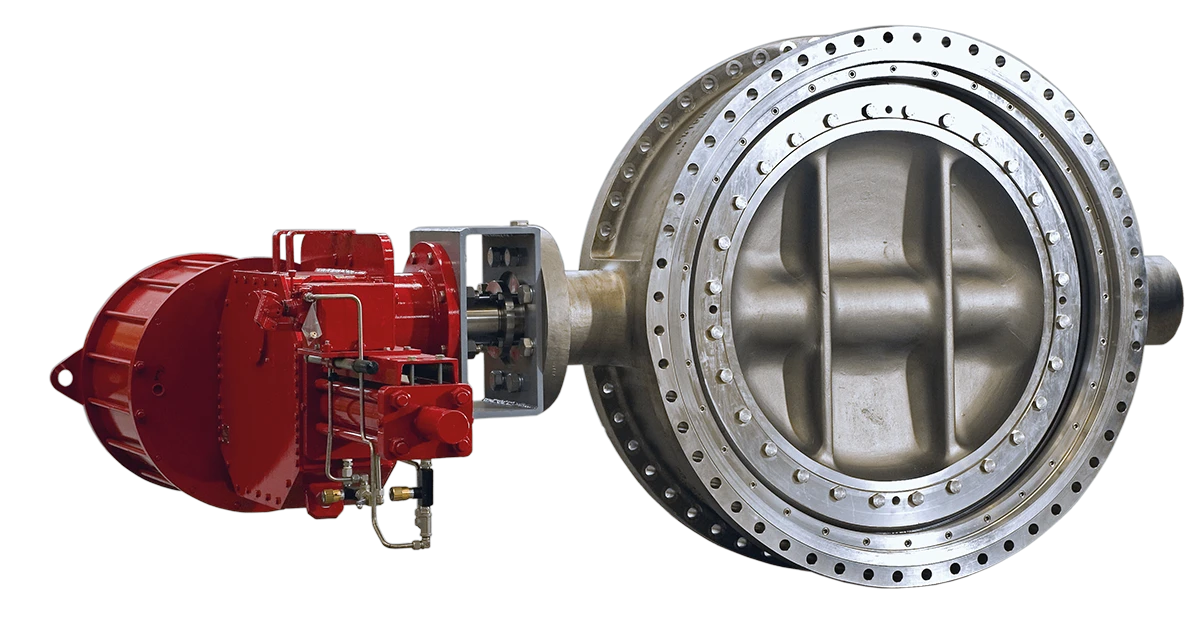

Isolation valves

Our precision-engineered rotary, slide, and gate valve solutions are designed for critical applications, providing you with a complete range of options to ensure maximum performance and reliability.

- Ball valves

- Butterfly valves

- Check valves

- Gate valves

- Purging systems

- Shut-off valves

- Slide valves

Safety valves

Ensuring safety is paramount in any critical application. Our safety valves are designed to prevent overpressure in pipe systems, pressure vessels, and boilers, ensuring the safety of your people, plant, and the environment. We offer a range of high and regular flow options to suit your specific needs.

Actuators

Ensuring reliable industrial valve operation is critical for the success of your operations. Our cutting-edge actuation technologies ensure industry-leading speed and response, so you can trust that your valves will operate as needed, when needed.

- Linear actuators

- Rotary actuators

- Positioners

- Safety valve actuators

- Stepper motor actuators

- Accessories

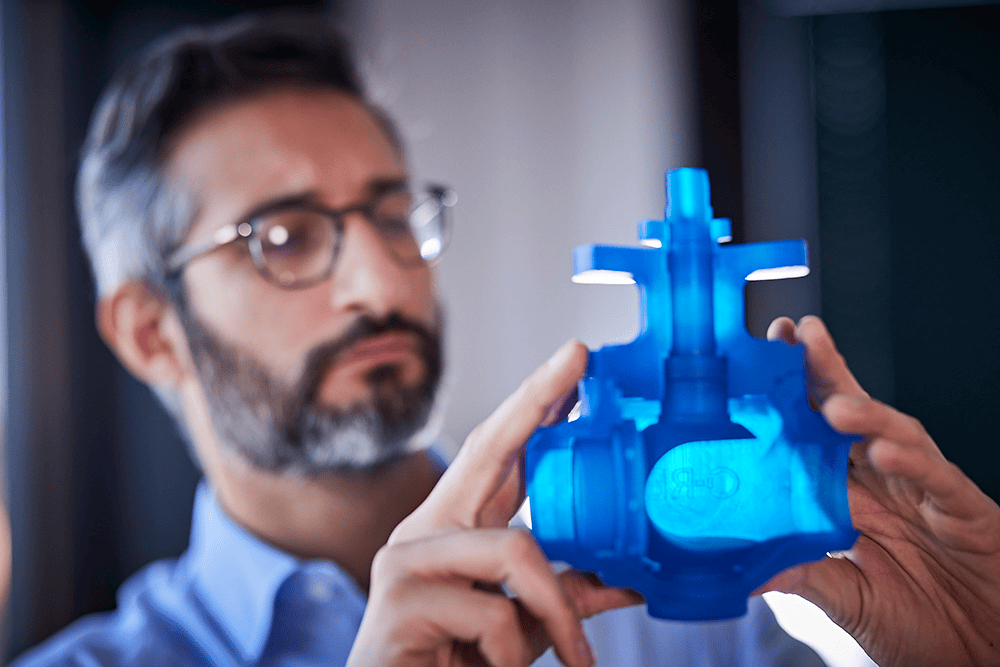

Passion for innovation

At IMI, we build trust and collaboration through custom actuator and valve solutions that solve your critical challenges. Our expertise in these technologies enables tailored, high-performing solutions. By understanding your goals and closely collaborating, we aim to deliver innovative, reliable products and service that satisfy and create lasting partnerships.

Customer centric approach

We specialise in bespoke and customised severe service valves and actuators. We prioritise customer satisfaction and strive to build long-term partnerships based on trust and collaboration. Our customer-centric approach involves closely understanding your unique requirements, challenges, and goals. We work together with you to develop customised valve and actuator solutions that address your specific severe service needs and deliver tangible results.

Global expertise and manufacturing

At the heart of our operations are over 2,900 talented and diverse individuals committed to delivering precision-engineered flow control solutions, expert installation, and lifetime servicing. With manufacturing facilities in 12 countries and a global service network, we are dedicated to providing you with unparalleled reliability and performance.

140

Years of engineering expertise

37

Countries supported

749980

Valves installed

Keeping industry flowing